DMAIC Process explained

DMAIC process: this article explains DMAIC Process in a practical way. This article contains a general defintion of the DMAIC Process, associated steps and practical examples. After reading you will understand the basics of this Six Sigma and problem solving tool. Enjoy reading!

What is a DMAIC Process? The basics explained

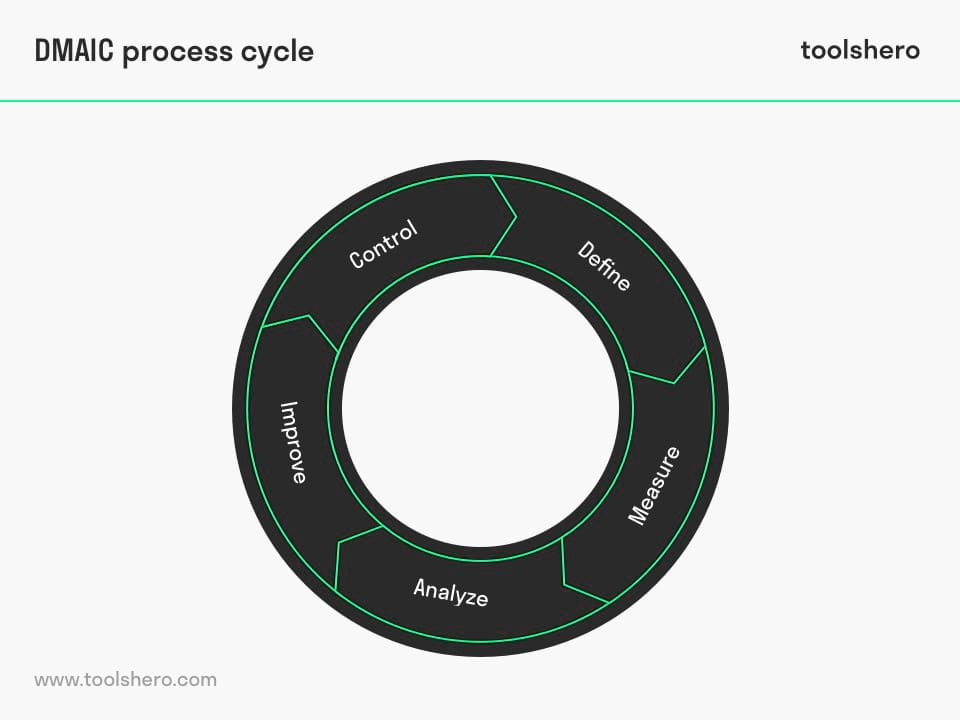

The DMAIC Process is a data driven problem solving tool that can be used to improve, optimize and stabilize business processes. This cyclical problem solving model seeks to improve the processes performance within an organization. The acronym of this Lean Six Sigma tool stands for: Define, Measure, Analyse, Improve and Control.

The base of this problem solving tool is founded by Shingeo Shingo during the development of Poka Yoke.

Five basic steps of the DMAIC Process cycle

The DMAIC Process consists of five steps that match the cycle process perfectly. It is recommended to make DMAIC an integral part of every project or organization. It can be applied to any existing processes.

Figure 1 – the DMAIC Process Cycle

Define

The problem is defined in this first step.Furthermore, it is important to recognize and define the following elements:

- who are the customers?

- what are the critical stages in the process?

- what is the objective and what are the related business processes?

Measure

The purpose of the measure phase of the DMAIC Process is to establish the most important aspects of the current process and to collect relevant data. The following aspects are important in this:

- analyse the output and the input

- define the measurement plan

- test the measurement system

Analyse

Subsequently, the data that was collected in the previous step is analysed. The purpose of this step is to identify the root cause relationships. The deeper causes of defects and errors are investigated. Basic tools are used to:

- identify the gap between current and required performance

- identify the input and the output

- list and prioritize potential opportunities to improve

Improve

The current process is improved by using techniques and creative solutions. Brainstorming sessions can be a useful tool. Other, obvious solutions are:

- innovative ideas

- focus on the simplest and easiest solutions

- create a detailed implementation plan

- implementation of improvements

- identify errors and causes using an Ishikawa diagram

Control

This step does not only focus on control but on monitoring as well. Control ensures that any deviations can be corrected in the future. Monitoring leads to sustainable improvements and guarantees long-term success. Permanent monitoring is therefore required.

Linking the DMAIC Process Cycle with business processes

To supplement the standard DMAIC Process, it is recommended to implement this step-by-step plan in other business processes as well. By sharing experiences and new knowledge with other departments, changes can be effected more easily within the entire organization.

It is important that employees have a good understanding of the usefulness of the procedure of the DMAIC process, that they discuss it with each other and that they are willing to share their experiences.

The DMAIC Process Cycle versus Six Sigma

Initially, the DMAIC process was linked to Six Sigma. Six Sigma was developed by Motorola and General Electrics to improve the quality of process outputs.

This is done by identifying and removing the causes of errors. The process is not exclusive to Six Sigma and can therefore be used to improve processes in other organizations.

Comparison of the DMAIC Process with the PDCA cycle (Deming)

DMAIC is actually an application of Deming’s PDCA cycle. The DMAIC Process takes a project based approach, whereas the PDCA cycle has a wider application.

This means it is can also be applied to one project. The DMAIC process analyses the root cause of the problem whereas the PDCA cycle focuses on the entire operation and it unearths other causes as well.

Benefits of using the DMAIC Process Cycle

The DMAIC Process is based on framework thinking within for example a product group, customer group or service. The strengths of this problem solving approach lie in the addressing and optimizing of the root causes in a process.

For a creative change in which an organization changes course completely, however, the model is less applicable. When going through the steps of the process, there may not be any overlaps. The best results are achieved with a plan-led team approach.

Example of the DMAIC Process

Let us look at a car garage with 50 locations who specialise in car tyres as an example. So far, in each branch, they have plenty of stock in various types of summer and winter tyres.

This enables them to quickly help the customer, delivering customer satisfaction and good word-of-mouth advertising. It now appears that the costs of the car company where very high last year. Management then decides to speak with all 50 branches in order to find out why.

Define

The costs have risen sharply due to employee costs, renting space for 50 branches and inventory.

Measure

The costs are compared to that of last year and it turns out the costs are 20% higher, without creating more revenue.

Analyse

Together with all 50 branches, the biggest cost item is examined. Several different factors are then identified. On average, it appears that inventory costs were 15% higher than in the previous year, among other things due to insufficient variety whereby ‘older’ models are left longer in the warehouse.

Improve

Together with the 50 branches, management looks at methods for improvement. For example, they propose to work from a central warehouse, supplying the branches 3x per week. Another option is to only have conventional tyres in stock while keeping specific tyre types in the central warehouse. The first solution is chosen unanimously.

Control

After a test period an evaluation takes place with all branches and management. It turns out that employees have to cancel a sale more often or only help customers after a few days.

After evaluation, they examine the other solution they had at their disposal and decide to stock conventional tyres and have the rest delivered from the central warehouse. This solution will of course also undergo an evaluation period and full cost overview.

It’s Your Turn

What do you think? Is the DMAIC Methodology applicable in today’s modern economy and companies? What is your experience? What tips can you share to help others being successful in applying the DMAIC process?

Share your experience and knowledge in the comments box below.

More information

- de Mast, J., & Lokkerbol, J. (2012). An analysis of the Six Sigma DMAIC method from the perspective of problem solving. International Journal of Production Economics, 139(2), 604-614.

- Pyzdek, T., & Keller, P. A. (2003). The six sigma handbook. McGraw-Hill.

- General Electric. (2006). Six Sigma. Available at: https://www.ge.com/sixsigma/. Accessed March 7, 2006.

How to cite this article:

Mulder, P. (2013). DMAIC Process. Retrieved [insert date] from Toolshero: https://www.toolshero.com/problem-solving/dmaic-process/

Original publication date: 05/28/2013 | Last update: 08/22/2023

Add a link to this page on your website:

<a href=”https://www.toolshero.com/problem-solving/dmaic-process/”>toolshero: Toolshero: DMAIC Process</a>