DMADV Process: the Basics and Steps

DMADV Process: this article describes the concept of the DMADV Process in a practical way. Next to what it is (including acronym), this article also highlights the phases and steps, the applications of this Process and DMAIC versus the DMADV Process. After reading you will understand the basics of this quality management tool. Enjoy reading!

What is the DMADV Process?

DMADV is a Six Sigma quality method that is used to design new processes, with the goal of delivering the final product to the client correctly. The goal of the DMADV Process is the creation of a high-quality product, whole keeping the customer and the customer’s need in mind during every phase of the project.

DMADV acronym

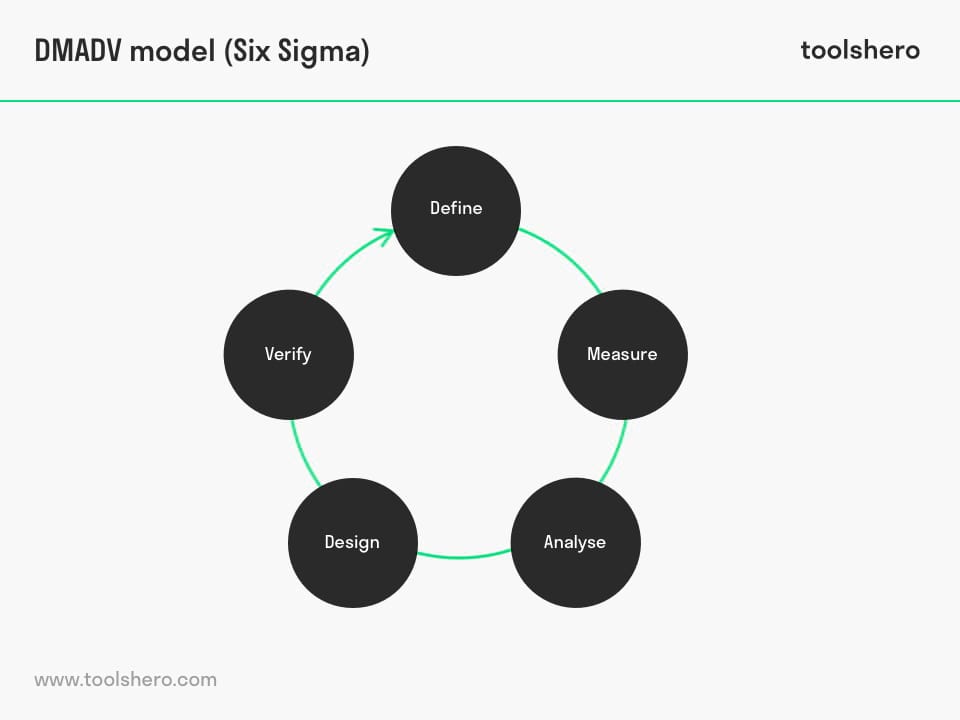

Each letter of the acronym DMADV is one of the five main phases of the project improvement initiative: Define, Measure, Analyse, Design en Verify.

Figure 1 – DMADV Process cycle

DMADV process is a Six Sigma method

Six Sigma is about process improvement as part of quality management. Existing products and/or services are improved using analytical techniques and statistics.

Six Sigma focuses on reducing variability in matters that are perceived as Critical to Quality (CTQ) by the customer. These CTQs are very important and vital to quality; it is about the internal critical quality parameters that relate to the customer’s wishes and needs. As such, CTQs are quality characteristics of the process or service that meet the requirements of the customer.

DMADV Process: phases and steps

DMADV is about the development of a new service, product or process. The DMADV Process is particularly useful for the implementing of new strategies and initiatives. Each phase is explained below.

Define

In this first phase of the DMADV Process, it is about identifying the goal of the project, the process or the service.

Not just from the perspective of the organisation, but also from the perspective of other stakeholders, including customers. It should be clearly defined which guidelines are important for the development of a product or service, and if there are any potential risks and what the production schedule is.

During this first phase, the project manager determines what the most important customer needs are regarding the product or service to be newly developed. He determines this by using relevant, previously gathered customer information and customer feedback.

In the definition phase, a garden furniture manufacturer can decide to focus on the production of wooden sun loungers. Based on previously collected customer information, the manufacturer knows it is very important to customers that the wood being used comes from fair trade.

In addition, customers have indicated that the lounger should be adjustable in three positions, have a high back support and head support and have an environmentally friendly coating that allows the lounger to be left outside. During this definition phase, the manufacturer can also determine if it would be lucrative to design such a sun lounger.

Measure

This phase of the DMADV Process is aimed at the collecting and recording of data that are relevant to the CTQ measures that have been identified during the first phase. The data that is collected during the measuring phase are essential to the process, as it will be used to drive the rest of the process.

In the case of DMADV, there are no CTQs in the measuring phase yet. After all, there is no new product yet, let alone a production process. During this measuring phase, it is about determining what the customer thinks is important about a new product.

These factors are subsequently linked to quality, which leads to CTQs. If a value is assigned to all design components, this leads to an effective approach to start the production process. It is important to determine which components of the production process are critical to all stakeholders.

The customer requirements will eventually be translated to clear project objectives, in order to get a product that can distinguish itself from the competition. The garden furniture manufacturer now links what the customers think is important to the CTQs. If it is not possible to source fair trade wood, production cannot start.

The same goes for the environmentally-friendly coating and the design that needs to meet the minimum requirements; 3 positions, high back support and head support. During this measuring phase, the manufacturer checks whether the design costs, manufacturing costs and raw materials costs are worth the eventual selling prise.

Analysis

The analysis phase of the DMADV Process is closely linked to the measuring phase, because the project team will analyse and test all the gathered data. This results in a good basis to measure improvements during the production process. During this analysis phase, design alternatives are developed and they determine the optimum combination of requirements.

An estimate of the total life cycle costs of the design is also made during this stage. After exploring the different design alternatives, a rough product design is created (functional specification) that meets the previously defined CTQ’s as much as possible.

In this phase, the garden furniture manufacturer will check out different importers from who they can purchase fair trade wood. They will determine the origin of the wood, so they can use it as background information for sales.

They also analyse different environmentally-friendly coatings, their advantages and disadvantages and the strengths of the different options. The analysis of different designs will receive close attention as well. Analysing is a time-consuming phase and the manufacturer would be wise to set a deadline to prevent cost-overruns.

Design

The design phase of the DMADV Process consists of the design of the product or service that fully matches the customer requirements. During this phase, the project team uses data from the previous phases, leading to a product that is suitable for the customer with all possible additional adjustments that might be needed.

It is a detailed and high-quality design which will be made into a prototype. During production of this prototype, they also look at the production process. The goal is not just to develop a production process that creates good products, but one which is also logistically efficient.

Based on the earlier analysis, the garden furniture manufacturer has made certain choices. They have found a supplier for fair-trade wood, know which environmentally-friendly coating they will use and they have chosen a design in which adjusting the lounger is quickest, safest and easiest and in which the back support and neck support are connected in a good way.

In the manufacturing process, close attention will have to be paid to the layout of the woodworking machinery and what route the process will follow (routing), so no time is wasted and an x number of loungers will leave the factory every hour.

Verify

The verification phase of the DMADV Process might be the final phase, but it is not the end of the process. To safeguard quality, it is important to continue to verify and make adjustment to the product where necessary. In this last phase, the design is final and the product is ready to be sold.

During this phase, the project team receives feedback from the customers and user experiences, and they will make necessary adjustments to better meet the customers’ needs. The project team will also determine additional CTQ measures to be able to monitor customer feedback after delivery of the final product.

During this phase, the garden furniture manufacturer feels it is very important to find out what its customers/users think of the wooden sun lounger. Are they satisfied about the fair-trade wood that was used, do they have sufficient information about the origin of the wood, do they find the lounger comfortable and is it user-friendly?

Is the head support pleasant and in line with the back support and is the coating sufficiently water resistant? If after six months it turns out that there are some complaints about annoying spots in the wood damaged by weather, then the coating might need to be changed. In that case, the garden furniture manufacturer will use the data collected earlier during the analysis phase to find a proper alternative.

DMADV Process applications

DMADV is mainly used for products or services that do not exist yet and still have to be developed by a company. In addition, it is also used for existing products or services that not yet meet certain customer specifications. For each DMADV Process improvement project, additional emphasis can be put on certain components, even though the goal remains the same; addressing a problem that has been identified and achieve the desired results.

A DMADV Process improvement project can take several months or even years, but the final result is a product or service that fully meets the customers’ needs and wishes.

DMAIC versus the DMADV Process

The DMADV Process is very similar to the DMAIC Process, which stands for Define – Measure – Analyze – Improve – Control.

Both methods are used in Six Sigma methodologies and in many respects they match. Both are designed to make business processes more efficient and effective. However, the models are not interchangeable and are used for different business processes.

However, there are some important differences. The first three letters in the acronym match. The biggest difference is the way in which the last two steps of both models take shape; DMAIC is about improving and controlling a business process. It defines a business process and its applicability, while the DMADV Process defines the customer’s needs, as it relates to the service or product.

The DMAIC Process measures current processes of a process, while the DMADV Process measures customer needs.

In addition, the DMAIC Process checks in the meantime to improve a business process and to reduce or even eliminate defects. At DMADV, it is about developing an appropriate business model that meets customer requirements.

It’s Your Turn

What do you think? What is your experience with the DMADV Process? Do you recognize the practical explanation or do you have more additions? What are your success factors for good problem solving?

Share your experience and knowledge in the comments box below.

More information

- Cronemyr, P. (2007). DMAIC and DMADV-differences, similarities and synergies. International Journal of Six Sigma and Competitive Advantage, 3(3), 193-209.

- Pyzdek, T., & Keller, P. A. (2003). The Six Sigma Handbook. McGraw-Hill.

- Jacobides, M. G., & Billinger, S. (2006). Designing the boundaries of the firm: From “make, buy, or ally” to the dynamic benefits of vertical architecture. Organization science, 17(2), 249-261.

- Johnson, J. A., Gitlow, H., Widener, S., & Popovich, E. (2006). Designing New Housing at the University of Miami: A “Six Sigma”© DMADV/DFSS Case Study. Quality Engineering, 18(3), 299-323.

How to cite this article:

Mulder, P. (2017). DMADV Process. Retrieved [insert date] from Toolshero: https://www.toolshero.com/quality-management/dmadv-process/

Published on: 10/03/2017 | Last update: 04/16/2024

Add a link to this page on your website:

<a href=”https://www.toolshero.com/quality-management/dmadv-process/”>Toolshero: DMADV Process</a>

One response to “DMADV Process: the Basics and Steps”

Very very nice