Drum Buffer Rope Theory explained

Drum Buffer Rope Theory: this article explains the Drum Buffer Rope Theory, developed by Eliyahu Goldratt, in a practical way. Next to what it is (Methodology), this article also highlights it’s origin, the pace of the Drum Buffer Rope Theory, the synchronisation and as a working method. After reading it, you will understand the basics of this quality management tool. Enjoy reading!

What is the Drum Buffer Rope Theory?

Israeli physicist Eliyahu Goldratt is the inventor of Drum Buffer Rope (DBR), as well as other concepts. DBR provides insight into the supply of products within the production process of an organisation; the supply chain.

This makes DBR a planning and scheduling solution, derived from another theory by Eliyahu Goldratt, the Theory of Constraints (ToC). This theory offers solutions for generic problems within organisations, which can be solved through the use of scientific methods.

Theory of Constraints (ToC) is a proven method that increases throughput and focuses on a reliable and high-quality stock.

ToC focuses on the process of continuous improvement within production systems. Possible limitations are brought to light, allowing organisations to focus on effective solutions. This methodology has a similar working method.

Pace

Each production process consists of a number of links, all of which make a proportional contribution to the end product. That is the basis of the Drum Buffer Rope Methodology.

It can be compared to a group of mountaineers or boy scouts walking up a mountain ridge in a row (pull system), connected by a rope. The pace of the group is determined by the slowest climber.

The quickest couldn’t possibly set the pace, as the others would be unable to keep up and get dragged along and worse. Letting the slowest walker determine the pace is practical, safest and, strangely enough, the fastest way.

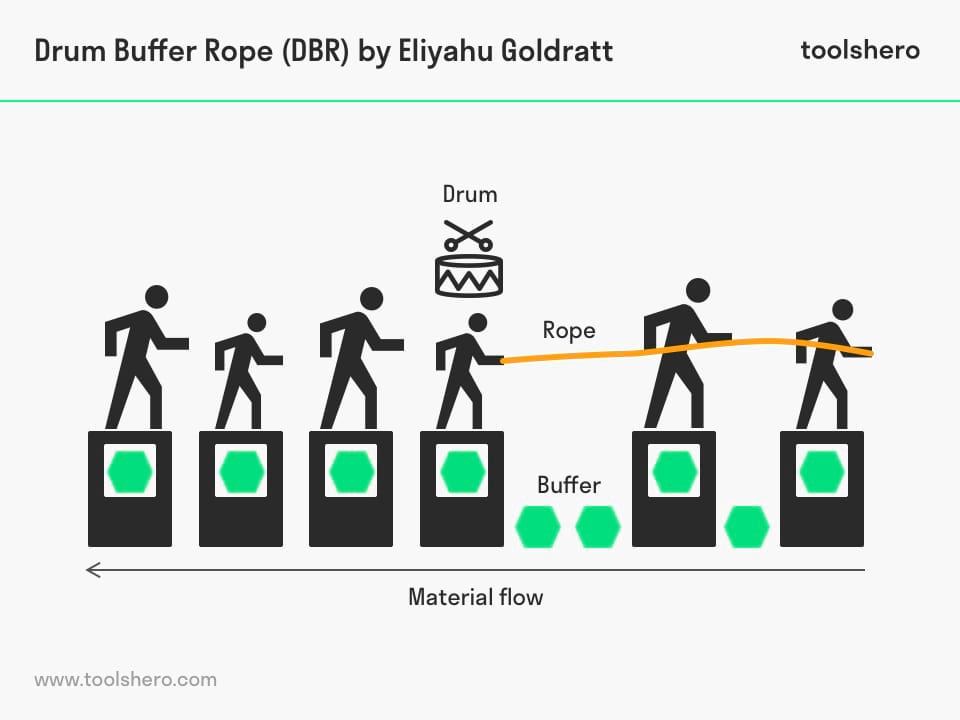

Here lies the basis of DBR, where a drum determines the rhythm and the rope connects the so-called links in the production process. This drum determines the speed of the production process.

For example, if raw materials are scarce, it will take longer for the end product to roll of the production line. In that case the drum will have a slower rhythm, also determining the pace for other raw materials. The (timely) detection of disruptions can allow the drum to go faster, maximising the output of the production process.

Figure 1 – Drum Buffer Rope effect

Synchronisation

As is the case with mountaineers, the slowest people will be placed in front; after all, they are the ones who determine the pace.

In the Drum Buffer Rope Theory, it’s useful to place possible bottlenecks in the production process / parts of the system in front of the line, allowing subsequent actions and supply to follow at the same pace.

The rope acts as a link between the work processes and is subordinated and synchronised to the speed of the initial work processes.

This prevents the work from stagnating and stops problems that are difficult to solve immediately from arising in the first place (work in front). Each process is dependent on another process. This is also known as serial interdependence.

Also, the pace of the bottlenecks must be prevented from slowing down the entire process. The rope that acts as a link plays an important buffer role in this and can accommodate the speed of the front bottlenecks. The tempo indicated by the drum transfers the pace to all intermediate work processes.

Theory of Constraints (TOC) and its Applications

The Drum Buffer Rope Theory as working method

DBR is characterised firstly by identifying the limitations or bottlenecks in the production process. This information can be used to determine the pace of the drum.

After that, you can apply the previously mentioned limitations. A detailed process diagram can now be drawn up, including the customer requirements and solutions for peak loads.

A buffer can also be included, which is used as extra time to protect the drum. This buffer time compensates for process variations, stabilising the production schedule and making it more resistant to potential problems.

As a result, the production process has the least chance of being overloaded and continuity is guaranteed.

The limitation of the Drum Buffer Rope Methodology

It can happen that the rope is stretched to its limit. In such a case, it’s necessary to impose a restriction on one of the work processes, so that the difference in pace does not increase any further.

It can even be decided to stop the entire production process when the buffer time has reached its limit as well. It’s a bit like letting off some steam from the kettle and calling a timely pause to avoid the fuses from blowing.

The pace of the drum shouldn’t be led and increased by that one link that works faster; the drum is the one that determines the pace.

The slower the pace, the lower the increase of the inventory level and the lower the level of production. The faster the pace the drum is able to determine, the more production it yields and the faster the stock level decreases.

It’s Your Turn

What do you think? Is the Drum Buffer Rope Theory applicable in your personal or professional environment? Do you recognize the practical explanation or do you have more suggestions? What are your success factors for good and lean process management?

Share your experience and knowledge in the comments box below.

More information

- Gardiner, S. C., Blackstone Jr, J. H., & Gardiner, L. R. (1993). Drum-buffer-rope and buffer management: impact on production management study and practices. International Journal of Operations & Production Management, 13(6), 68-78.

- Ghorse, K. (2020). Theory of Constraints (TOC) & its Applications. Retrieved 01/11/2024 from Udemy.

- Goldratt, E. M. (2003). Production the TOC way. North river press.

- Schragenheim, E., & Ronen, B. (1990). Drum-buffer-rope shop floor control. Production and Inventory Management Journal, 31(3), 18-22.

How to cite this article:

Mulder, P. (2018). Drum Buffer Rope Theory. Retrieved [insert date] from toolshero: https://www.toolshero.com/quality-management/drum-buffer-rope/

Original publication date: 06/15/2018 | Last update: 01/11/2024

Add a link to this page on your website:

<a href=”https://www.toolshero.com/quality-management/drum-buffer-rope/”>toolshero: Drum Buffer Rope Theory</a>