LEAN Manufacturing: theory, principles and tools

LEAN Manufacturing: this article explains the philosophy of LEAN Manufacturing in a practical way. The article starts with the definition of LEAN Manufacturing, followed by information about its origin and a visualisation of its goals and principles. The article further discusses various tools that are connected to this discipline, and topics like waste. Enjoy reading!

What is LEAN Manufacturing?

Definition

LEAN Manafacturing is a production management philosophy. LEAN Manufacturing or LEAN Management originates from the Japanese car manufacturer Toyota. LEAN Manufacturing literally means lean production. Taiichi Ohno is considered the father of LEAN.

Toyota plays close attention to the proportional relationship between high production and high-quality at low costs, which leads towards an improvement of the operating results. LEAN is sometimes referred to as the Toyota Production System (TPS).

This philosophy targets the prevention and elimination of Muda in manufacturing processes, the Japanese expression for waste. All that is Muda does not deliver added value.

History

This management method is often wrongly considered to be a Japanese method. LEAN Manufacturing is largely based on British and American principles (Henry Ford and W. Edwards Deming) which were spread and introduced in Japan through American reconstruction work after the Second World War.

Toyota Production System (TPS), the first foundations of LEAN Manufacturing, was largely developed by Sakichi Toyoda, the founder of Toyota, and it was further developed by engineer Shigeo Shingo. By applying TPS, Toyota succeeded in reducing cost and thus became one of the top ten of multinational corporations.

TPS is considered to be the classic example of the Gemba Kaizen approach that is aimed at production improvement.

LEAN Manufacturing: the common goal

In LEAN Manufacturing many established methods are used. All these methods have in common that they aim at identifying problems, eliminating unnecessary steps, combining several steps into one step and the solving and preventing of problems.

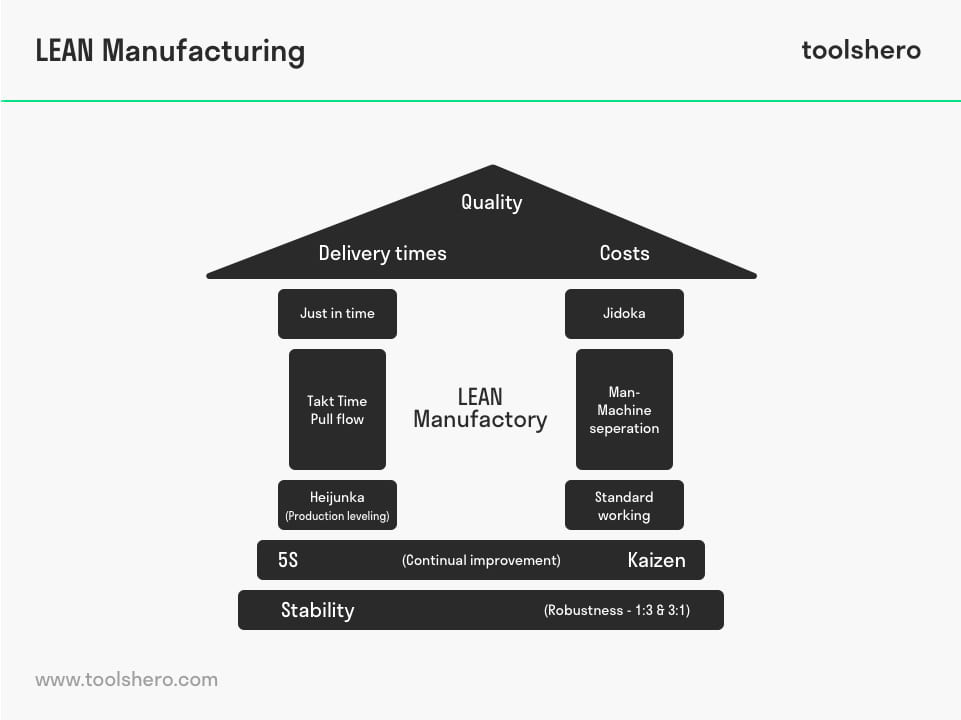

LEAN Manufacturing is sometimes symbolically represented as a house, based on a solid foundation and built up from all these established methods.

Figure 1 – LEAN Manufacturing house model

Base of LEAN Manufacturing

The base of LEAN is formed by a multifunctional team that pre-assesses the used materials and the process. This team consists of several employees from different departments, from production and research to accountants.

They have the task to pre calculate the costs of all steps so that it becomes clear where e profits may be gained. In their assessment decisions are considered about make-or-buy or re-engineering.

Organizations that use LEAN Manufacturing

Toyota especially uses this method fully, because of which Toyota has built up a lead in cost control compared to their competitors. Besides Toyota, several other multinational companies use the LEAN method successfully: for example General Motors, Scania and Volkswagen.

Moreover, more and more large (manufacturing) companies switch over to LEAN.

Flow in lean production systems

Flow refers to the flow of products and information, and the progress of work. A system with a good flow will tend to manoeuvre steadfastly and predictably. When there is a bad flow, the flow of work will be unpredictable and riddled with faults.

Every chance of the occurrence of a fault in the flow of work and value will increase the chance of accumulation of waste (muda). And every type of wastefulness, be it Mura, Muda or Muri, will result in an inconsistent production process.

Mike Wroblewski, Senior Consultant for Gemba Consulting, explains that there seven types of flow within a production unit.

- The flow of raw materials

- The flow of work in progress

- The flow of finished products

- The flow of operators

- The flow of machines

- The flow of information

- The flow of engineering

Businesses who have applied the principles of Lean manufacturing successfully understand that each of these types of flow must work together in harmony, thereby increasing the chance that finished products and services will be produced without the need for correction measures.

By keeping production in such a flow, the organisation will ensure that a business is on the road to efficiency, and will eventually achieve such efficiency.

The Lean methodology has three times Mu

Within the Lean methodology there are three main categories, all starting with ‘Mu’:

Muri

Muri is the Japanese term for overburdening people and equipment. Muri is everything contributing to this overburdening.

In practice, Muri results in staff with burnouts caused by doing too much work that they cannot delegate. Muri can also cause the total breakdown of a machine. An example of this is when a machine has to produce more than its maximum capacity.

Mura

Mura refers to the unevenness of processes; excess resources used in production by inadequate coordination of the amounts of production resources required. Mura is anything that creates this unevenness; anything that causes inconsistencies and inefficiencies.

An example of Mura is when a lorry is ten pallets of materials short in its trailer of the maximum capacity for 1 journey, but then has to carry more than it is able in 1 go for the second journey. This will result in unnecessarily long lead times.

There are more isses that can be classified as Mura. Examples of inconsistencies are the fluctuations in consumer demand, lead times, or various product phases.

In a production environment with a low capacity and high product variety, flexibility will be more important than in a production facility with higher volume and low product variety.

Mura is considered to be cause Muri and Muda where it is not mitigated. Mura can be mitigated by creating total transparency in the supply chain, as well as in other organisational processes such as product design.

Muda

Muda is the Japanese term for waste. Muda is anything creating waste during a particular production process, and impedes the production of something valuable.

It is common knowledge that a large part of organisational processes does not add value to the end product. Various (muda) dangers lurk around the corner. The TPS approach mentions eight of these.

1. Neglecting talent

Not capitalising on talent is increasingly regarded as waste. Rightly so. Organisations are made up of individuals, and each of these will come with their own talents, skills and knowledge. If these are not utilised when chasing business goals, the organisation will not come to its full strength.

2. Waiting

Waste will also arise when people or machines working on production have to wait for whatever reason. When the work stops, the flow does too, as does the flow and creation of value to the end user. Work can be halted for various reasons: a faulty machine, something that is no longer in stock, waiting for someone’s approval.

3. Over production

Waste also means producing something that cannot be sold on. This problem arises when consumers are not yet ready to receive the product, or do not need it, yet staff continues to produce unnecessarily.

4. Defects

Mistakes are human, and will always be made. In spite of this, Lean does strive for near-perfect production.

An important pillar in this is Zero Defects. Zero Defects aims to reduce the number of errors to an absolute minimum. Correcting mistakes, after all, costs time, money and other resources.

5. Transport

Where there is too much transport, in whichever way, the risk of product damage and deterioration increases. It also leads to an increase of expenses and time-wasting. Muda.

6. Overstock

Where supply exceeds consumer demand, goods or services will remain unused. This costs money in various ways, such as shelf life and depreciation, as well as the higher cost of storage. Another issue is that stock levels will mask true customer demand.

7. Over-processing

These are processes where more work goes into the process itself than it delivers in value.

8. Waste of motion

Any unnecessary action results in waste. This is because everything within an organisation should be at the service of adding value to the product or service.

Reducing waste

Reducing or eliminating Mura, Muri and Muda will ensure the highest quality standard in production. This means that each process, regardless of which one it is, must be improved and perfected. Proponents of TPS and the Lean production system believe that a business can only receive production perfection by performing these three activities successfully and continuously. This will result in increased turnover and productivity.

Various tools can be applied to reduce waste. Many of these tools have been elaborated on in other Toolshero articles.

Lean Manufacturing A-Z: Lean Operations Management

LEAN Manufacturing tools

To succesfully eliminate Mura, Muri and Muda, the following devices can be used:

- 5S system

- Just-In-Time (JIT)

- Gemba Kaizen

- Value Stream Mapping

- Kanban

- Bottleneck

- Jidoka

- Continuous flow

- PDCA

LEAN Manufacturing advantages

One big advantage of the LEAN Manufacturing is the relationship between cost saving and improvement of productivity and quality. In LEAN Manufacturing, all energy and creativity within an organization are geared towards optimizing the aspects that are valuable for the customer.

This includes among other things, price, quality, delivery time, maintenance costs and environmental tax. In addition, it appears that internal factors such as safety, occupational hygiene and ergonomics often improve as well.

LEAN Manufacturing implementation

Switching to a Lean production process sounds more complicated than it is. There is an incorrect assumption that existing production processes must unreservedly be revamped in full. While this may indeed be true in some cases, no big changes are necessary if production is already well-organised.

After advising all staff of the coming changes, the following five Lean principles can be applied to implement Lean in the current production process.

1. Identify value

Firstly, it is important to identify the value of the team. Some teams do not produce immediate value to a customer of the business, but do add immediate value to the organisation as a whole. You must also identify all types of waste within the business.

2. Use Value Stream Mapping

Next, it is paramount that the path to the client is visualised. This can be done using Kanban boards. This allows for the mapping of each step in a particular process, thereby visualising the value stream of teams. As an alternative, Business Process Mapping (BPM) can be used for this.

3. Create flow

Flow is a key concept in Lean management. Waiting of any sort is waste, so a constant stream of valuable activities is crucial. An important obstacle to achieving flow is the removal of bottlenecks in the process. Monitor closely where activities and tasks get stuck, and how it can be fixed.

4. Ensure pull

Once the work has started to flow to a satisfactory level, a pull system must be put in place. This means that new work will not be started until there is a demand for it. The aim is to produce products that customers really want, and to prevent over-production.

Jobs to be processed are registered in a pull system. Anyone not working on anything accesses this database and chooses the activity with the highest priority.

5. Continuous improvement

Only through continuous monitoring and continuous improvement of production processes can near-perfection be achieved. Continuous improvement can be achieved using tools such as PDCA, but it is in essence a mentality to be adopted by staff.

LEAN Manufacturing principles

In addition to having advantages the LEAN management has a number of characteristic features and principles:

- level hierarchy

- more responsibility and competence at the basis of an organization

- discouraging and eliminating of losses

- improved communication with customers and suppliers

- focus on that which is important

- improved customer friendliness

Disadvantages of LEAN Manufacturing

Because an organization fully aims at improving the existing product with LEAN Manufacturing, the opportunities for discovering innovative, new techniques decrease.

In addition, the introduction of a successful system requires far-reaching preparations, whereas the results are not immediately noticeable in the short term. Moreover it is often underestimated that changing over from short-term thinking to long-term interest rates requires much time and effort for employees.

It’s Your Turn

What do you think? Is LEAN Manufacturing applicable in today’s modern economy and companies? Is LEAN applied in your working environment? Do you recognize the practical explanation or do you have more suggestions? What are your success factors for a successful LEAN implementation?

Share your experience and knowledge in the comments box below.

More information

- Arnheiter, E. D., & Maleyeff, J. (2005). The integration of lean management and Six Sigma. The TQM magazine, 17(1), 5-18.

- Myerson, P. (2012). Lean supply chain and logistics management. McGraw-Hill.

- Salah, S., Rahim, A., & Carretero, J. A. (2010). The integration of Six Sigma and lean management. International Journal of Lean Six Sigma, 1(3), 249-274.

- Womack, J. (2011). GEMBA walk. Lean Enterprise Institute, USA.

How to cite this article:

Janse, B. (2020). LEAN Manufacturing. Retrieved [insert date] from Toolshero: https://www.toolshero.com/quality-management/lean-manufacturing/

Original publication date: 08/25/2020 | Last update: 12/21/2023

Add a link to this page on your website:

<a href=”https://www.toolshero.com/quality-management/lean-manufacturing/”>Toolshero: LEAN Manufacturing</a>