Poka Yoke explained including an example

Poka Yoke: this article explains the Poka Yoke method, developed by Shigeo Shingo in a practical way. After reading it, you will understand the basics of this powerful quality management tool for production systems. Highlights include: what is poka yoke, how to implement the 5 stages, 3 types of poka yoke and a practical poka yoke example. Enjoy reading!

What is Poka Yoke?

The definition and meaning of Poka Yoke

Poka Yoke is a Japanese phrase that means error prevention. It was developed in the sixties of the previous century by Shigeo Shingo from Japan. He was an engineer at the Toyota car factory.

The Toyota production system is still the most effective manufacturer using Poka Yoke today and comes close to error proof manufacturing.

The method is used to prevent defects and resolve them during the production process in industrial engineering, eliminating human quality control after the process.

Poka Yoke is a frequently used method in Lean Manufacturing and Six Sigma to ensure as little errors in a production process as possible.

A ‘poka’ is an ‘inadvertent error’ and ‘yokeru’ is Japanese for ‘preventing’.

Poka Yoke makes it practically impossible to have processing errors. It forces actions to be carried out correctly, leaving no room for misunderstandings and / or human error. It’s about measures that prevent further errors from being made.

Many solutions based on this concept tend to be simple, cheap, and effective. They can be integrated into the product design or in one of the process steps.

A good example is smartphone SIM cards. After all, there’s only one way to place the SIM card in the phone. It’s impossible to do it wrong. It therefore is a mistake proofing device.

Another example of a solution based on this concept is digital spell checks. The Poka Yoka process helps manufacturers with eliminating defects that have occured, but in the first place to prevent defects from occuring.

Many technological inventions have been based on this concept. Examples are control systems, contact methods, fixed-value methods, motion-steps methods and sensing devices. Some of these solutions are used very often, like limit switches, touch switches and proximity switches.

Orgininally, Poka Yoke was named Baka Yoke. This literally means idiot proofing, and was replaced with the milder mistake proofing Poka Yoke.

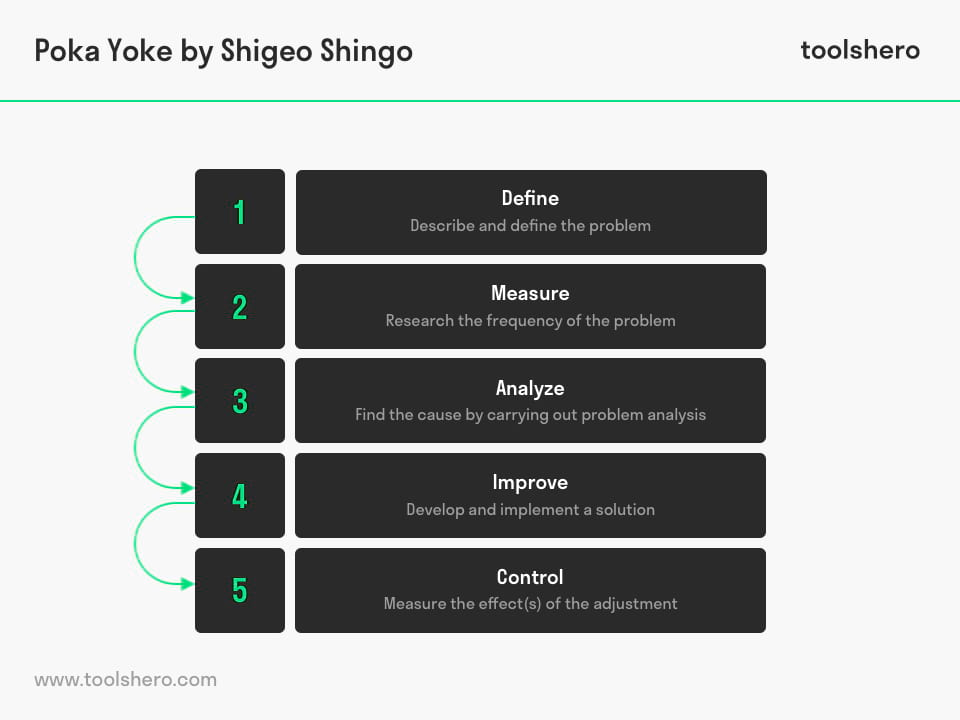

Implementing Poka Yoke Stages for Process Improvement

In order to carry out Poka Yoke techniques as well as possible, it’s a good idea to work in stages. The example at the end of this article will also refer to those stages.

1. Define

During this phase, the problem causing the defect is described and defined. It needs to be an objective description that doesn’t draw conclusions right away. It’s possible to monitor the shop floor during the production process.

This is also indicated with the word ‘Gemba’, which is Japanese for shop floor. The shop floor is where the process happens, and that’s where the causes of problems may also be hiding.

If the problem occurs at the end user, it’s a good idea to define the problem objectively from this perspective.

2. Measure

Usually, the measuring stage is applied in case of complex problems in the production process. A test is used to discover how often the problem occurs. A percentage is then calculated based on the results.

The higher the percentage, the more important it is to solve the problem at its source. Apart from a production error, it may also be a case of user error.

In such a case, a so-called test group would be used that tests the product over a certain period. The outcome of this determines how the problem will be dealt with and solved.

3. Analyse

During this stage, it becomes clear whether a Poka Yoke measure can be applied. The process is analysed thoroughly, and the cause of the defect is tracked down. Only when the source of the issue is clear, can the search for a solution begin.

4. Improve

During this phase, analysis is used to deal with the cause of the problem. A solution is developed and implemented. In many cases, Poka Yoke solutions seem obvious, but have a significant positive impact. They prevent the same mistake from being made in the future.

5. Control

During this stage, the effect of the changes is measured. If the measure in question works well, and the chance of further potential error is negligible, it concludes with the ‘Zero Quality Control’ (ZQC) and Zero Defects.

Figure 1 – The Five Stages of Poka Yoke

3 types of Poka Yoke

Three types of Poka Yoke can be identified for quickly and easily delivering solutions for production problems.

1. Visual aids

These aids are clear and show the work instructions. These may be pictograms in a user manual or a traffic sign that shows a restriction or warning.

2. Visual control, the second type of Poka Yoke

These refer to directing behaviour and warning in case of deviations. One example would be a traffic sign that lights up red when drivers are speeding and green if they stick to the speed limit.

3. Fail-safes, the third type of Poka Yoke

They force the user to either do or not do something. This can be road closures for motorway maintenance, for instance.

Arrows on signs force drivers to go from 3 to 2 and from 2 to 1 lanes. The arrows are followed by red Xs on the signs until 2 of the 3 lanes are closed.

Learn POKA-YOKE: Error Proofing Technique of Quality

A Poka Yoke example

The Netherlands (Europe) has a lot of commuters on bicycles. They also go out on their bikes in the rain. Comfortable waterproof clothing offers a solution. In this example, we assume that waterproof clothing are decent-quality overalls.

The overalls are easy to put on and have a soft fleece lining. They are also durable and strong for long bike trips and everyday use, and are made of light polyamide material with reflective stripes.

The overalls have a zip closure on the front that goes down. The zip is a precarious part of the rain overalls, since it lets through water and wind. In order to limit this, there is a cover along the length of the zip that can be closed using velcro.

Getting in and out of the rain overalls still presents difficulties, and tears and holes form at the base of the zip. In order to solve this problem, we will consider it step by step.

Define

We start by objectively identifying the problem. When putting on the rain or taking off the rain overalls, tears form at the base of the zip over time.

When defining the problem, you can observe how the overalls are put on, how they are taken off, and in what order; left leg first, followed by right leg (or vice versa), pulling the overalls up, then left arm and right arm (or vice versa), pull the zip up, pull the hood up, and finally close the cover over the zip and secure the velcro.

Taking off the overalls is done in the opposite order.

Measure

It’s not always necessary to measure. If this is the case, one group could put on and take off the rain overalls an x number of times over an x number of days.

Sample testing can then identify how many of the test subjects had a pair of rain overalls that had developed tears at the base of the zip at the end of the test period.

Analysis

In order to get a good idea of where the problem is, it’s a good idea to look closely at what happens when the overalls are put on and taken off by the test group. It turns out the velcro isn’t the issue, but the zip is.

The light polyamide material the rain overalls are made of isn’t flexible enough when they’re put on or taken off.

This puts pressure on the zip, particularly the lower part, which leads to tears forming more easily in this area.

Improve

Now that we know how the tears are formed at the base of the zip, we can consider adjustment. The rest of the rain overalls is fine, and the material has no problems and keeps out the wind and rain. The zip has a traditional vertical orientation. The solution is easier than expected.

By sewing the zip into the overalls diagonally, there’s less pressure on the base of the zip when getting into or out of them. This reduces the risk of tearing and holes. The velcro is sown diagonally along the zip to stop wind and rain from coming through.

Control

The overalls can go into production and be shipped to shops. In order to be absolutely sure that this is the right solution for the tearing at the base of the zipper, they may employ another test group, just like during the measure stage.

Poka Yoke isn’t about the test and measuring results as much as it is about finding the actual solution.

It’s Your Turn

What do you think? Is the concept of Poka Yoke applicable in your personal or professional environment? Do you recognize the practical explanation or do you have more suggestions? What are your success factors for good quality management?

Share your experience and knowledge in the comments box below.

More information

- Fisher, M. (1999). Process improvement by poka-yoke. Work Study, 48(7), 264-266.

- Shingo, S. (1986). Zero quality control: Source inspection and the poka-yoke system. CRC Press.

- Shimbun, N. K. (1989). Poka-yoke: Improving product quality by preventing defects. CRC Press.

How to cite this article:

Mulder, P. (2018). Poka Yoke. Retrieved [insert date] from Toolshero: https://www.toolshero.com/quality-management/poka-yoke/

Original publication date: 03/14/2018 | Last update: 12/27/2023

Add a link to this page on your website:

<a href=”https://www.toolshero.com/quality-management/poka-yoke/”>Toolshero: Poka Yoke</a>