Reliability Centered Maintenance (RCM)

Reliability Centered Maintenance (RCM): this article provides a practical explanation of the concept of Reliability Centered Maintenance (RCM). After reading, you will have a basic understanding of this powerful quality management tool.

What is Reliability Centered Maintenance (RCM)?

Reliability Centered Maintenance (RCM) is an improvement method within maintenance management. Its primary aim is to increase the reliability of manufacturing machines. Reliability Centered Maintenance (RCM) mainly tries to prevent machine failures that could lead to consequential damages.

Reliability Centered Maintenance (RCM) is a maintenance strategy at a company level, which is implemented in order to optimise businesses maintenance programmes.

Reliability, uptime, product quality, and cost effectiveness will be improved, provided it’s done in compliance with conditions set by safety and environmental laws and regulations. Reliability Centered Maintenance (RCM) is often employed for machines with a high safety risk, when there are high requirements regarding uptime, or if downtime of certain machines would lead to significant costs. The purpose is to prevent the consequences of failures.

History

Reliability Centered Maintenance (RCM) focuses on all situations in which reliability or availability of machines is of crucial importance. The foundation of RCM can be found in the aviation industry. In the 1960s, aircraft manufacturer Boeing looked into the maintenance costs for the Boeing 747.

At that time, this aircraft type was larger and more complex than any existing aircraft Boeing had, and the standard preventative maintenance plan proved insufficient. It was usually believed that chances of failure increased as parts aged.

However, it turned out that some parts of the Boeing 747 would break more frequently when they were new. That’s why they looked specifically at the consequences of failures when creating a new maintenance plan. A broken bathroom light has less harmful consequences than a broken low-fuel warning light in the cockpit, for instance.

Boeing’s maintenance programme was eventually further elaborated by the American Aviation Agency, with maintenance planning solely being focused on increasing equipment reliability. In the 1970s, the method was adopted by the American armed forces and RCM became an official improvement method. Later it was also successfully applied in nuclear power stations, railways, and chemical factories.

FMEA

RCM uses a number of terms. The first one is ‘Maintainable Units’. This refers to the different parts of a machine for which a separate maintenance programme can be drawn up. Another term is ‘Functional Breakdown’, which is about splitting up a system in increasingly small functional components.

Eventually, what you’re left with is the ‘maintainable units’. The term ‘Failure Mode and Effect Analysis’ (FMEA) is also frequently used. This is a step-by step method for determining a maintenance programme per maintainable unit. It’s important to first describe the desired situation for each machine component.

After that, the possible failures that might occur are investigated, as well as the effect they would have on the functioning of the maintainable unit. The consequences are described in terms of impact on production, environment, safety, and repair costs. That way, an FMEA systematically shows what possible malfunctions there are and what the consequences would be.

Sometimes, FMEA is also used as part of other improvement methods, such as Lean and Six Sigma. In that case, FMEA is a means to track problem causes and consequences. FMEA is regularly used within Reliability Centered Maintenance (RCM) as a tool for improvement methods.

Multi-disciplinary

Reliability Centered Maintenance (RCM) requires a multi-disciplinary team to systematically analyse all possible sources of malfunctions, failures, and the effects of those. Both the people who know exactly how machines work and the people who are knowledgeable about the production process as a whole take part in the improvement process.

Each can say what the equipment is used for specifically. Reliability Centered Maintenance (RCM) mainly focuses on inventory beforehand and preventing the effects of possible failures. The various employees can contribute their knowledge and experience to consider this in advance.

The power of Reliability Centered Maintenance (RCM) is its analysis of critical system failures and the consequences thereof down to the smallest details. Next, a selection is made of suitable strategies for managing the risks that have been raised. Each strategy is then selected based on the technical feasibility and costs accompanying the completion of the task.

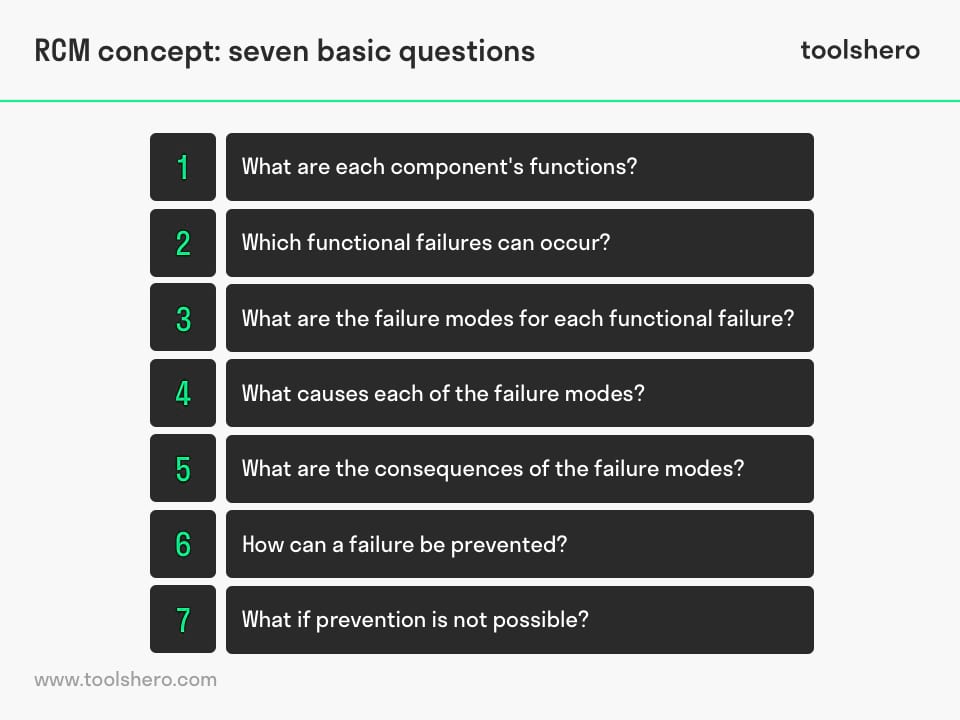

Seven Basic Questions

Central to Reliability Centered Maintenance (RCM) are seven basic questions that help determine the cost-effective maintenance task for every possible malfunction in a structured way. The seven questions that have to be asked can be seen as a step-by-step plan:

Question 1 – What are each component’s functions?

In order to determine the maintenance tasks a system needs, you first have to know which functions the equipment has to fulfill and what the desired performance standards are. The first step is, therefore, to select the equipment. This selected equipment has to be critical in terms of effectiveness, earlier repair costs, and earlier preventative maintenance costs.

Question 2 – Which functional failures can occur?

Then, it’s determined which failures would mean that the equipment no longer meets the required performance level. This so-called functional failure can lead to a partial or total downtime. It’s therefore smart to define the limits and function of the failures.

Question 3 – What are the failure modes for each functional failure?

Every possible failure mode for each failure is listed. This can be human error, external influences, and ageing, wear or quick failure of parts. By defining the ways in which the system or the equipment can fail, you can identify the failure modes.

Question 4 – What causes each of the failure modes?

By describing the failure effect, its urgency becomes clear, and the main cause can be more easily tracked and identified. The entire multi-disciplinary can contribute to this. With the help of operators, experienced engineers, and maintenance technicians, for instance, the main causes of each of the failure modes can be investigated.

Question 5 – What are the consequences of the failure modes?

This step involves looking at the effects of every malfunction. For instance, complete downtime of equipment may affect safety or other devises that are linked to it.

Here they also look at which failure mode has the most significant consequences. The consequences of each form of failure are now being mapped out in terms of costs, safety, health and the environment, among other things. All this information is important for determining the consequences of the failure.

Question 6 – How can a failure be prevented?

Like the last step showed, not every failure is of equal importance. Preventive action is less critical for failures with minimal consequences.

Still, a maintenance tactic will have to be chosen in advance for each failure mode. That chosen maintenance tactic will also need to be technically and economically feasible.

Question 7 – What if prevention is not possible?

The final step focuses on preventative tasks that are established periodically. Examples would be planned overhauls, replacement, or inspections to prevent and/or identify a possible malfunction.

During this step, the question must be asked what would happen if a preventative measure is not possible.

In that case, different actions will need to be taken. This can mean design changes, total replacement of the system, or accepting the failure as it is, including the consequences.

Maintenance Tasks

Both scheduled maintenance tasks and one-time changes can be implemented within Reliability Centered Maintenance (RCM). Scheduled maintenance tasks have a periodical timeline that involves functional tests, preventative replacement of parts, maintenance, or a combination of those.

In the case of one-time changes, question 7 will apply. That means choosing to wait until a failure occurs. Action will also be taken in the event of changing rules and procedures.

The same goes in case of certain instructions that are given, or a physical redesign of the equipment. Sometimes changes to the equipment are implemented as well, if the client wishes.

In all these cases, there is the option to have spare parts ready and available in advance, in order to limit repair times as much as possible.

Now it’s your turn

What do you think? Do you recognize the explanation of the Reliability Centered Maintenance (RCM) concept? What are your experiences with this methodology and do you see it as a valuable tool? Do you have tips or additions about increasing the reliability of manufacturing machines?

Share your experience and knowledge in the comments box below.

More information

- Moubray, J. (1997). Reliability-centered maintenance. Industrial Press Inc..

- Nowlan, F. S., & Heap, H. F. (1978). Reliability-centered maintenance. United Air Lines Inc San Francisco Ca.

- Rausand, M. (1998). Reliability centered maintenance. Reliability Engineering & System Safety, 60(2), 121-132.

How to cite this article:

Mulder, P. (2019). Reliability Centered Maintenance (RCM). Retrieved [insert date] from Toolshero: https://www.toolshero.com/quality-management/reliability-centered-maintenance-rcm/

Published on: 07/11/2019 | Last update: 10/05/2022

Add a link to this page on your website:

<a href=”https://www.toolshero.com/quality-management/reliability-centered-maintenance-rcm/”>Toolshero: Reliability Centered Maintenance (RCM)</a>