Total Productive Maintenance (TPM)

Total Productive Maintenance: this article explains the Total Productive Maintenance / TPM in a practical way. After reading you will understand the basics of this powerful quality and process management method.

What is Total Productive Maintenance (TPM)?

Almost all industrial production processes are carried out with the aid of machines, as a result of which each production-oriented organization is largely dependent on its machinery. When a breakdown or a long-term disruption occurs of machines, equipment or important tools, this will automatically have far-reaching consequences for the total production.

Total productive maintenance (TPM) is a method of maintaining and improving the integrity of production and quality systems through the machines, equipment, employees and the supporting processes. TPM can be of great value and its target is to improve core business processes.

The phrase TPM was first used in 1961 by the Japanese company Denso. This supplier to the automotive industry, carried out an improvement project with continuous improvement as their starting point and they introduced autonomous and preventive maintenance to machines. TPM is especially meant for companies with a lot of machines that involve high maintenance costs.

Total Productive Maintenance (TPM) and Productivity improvement

TPM is not just about maintaining productivity but also about the maintenance of machines and the prevention of possible breakdowns. TPM is about productivity improvement and optimization of machine availability through which machines operate at their optimal level.

Everyone within the organization has to be aware of the hidden losses with respect to machine failure or the time needed for machine repair. Also, when a machine cannot run at full speed or produces inferior products, this is considered to be a loss-making activity for the organization.

The aim is to have an Overall Equipment Effectiveness (OEE) score of 100% and this represents perfect production. In that case, machines always work at full speed and deliver products of perfect quality.

Total Productive Maintenance (TPM) as a preventive maintenance concept

Running machines until they break down is not an option. Curative maintenance is characterized by waiting for a breakdown to happen which will consequently be repaired. Especially when productions need to continue round the clock, this type of maintenance is far too costly.

TPM puts machinery at the heart of the organization and does not just safeguard production continuously but improves it where possible. TPM focuses on productivity improvement and its primary purpose is to maximize availability of machines.

Everyone is responsible

The starting point of TPM is that everyone is responsible for the day-to day maintenance of the machines. Employee participation in improvement proposals and maintenance are key features within TPM, so that they can jointly improve the machine efficiency, step-by-step.

Maintenance therefore also means ‘improvement’. Machines are purchased for their intended purpose only. After that, it is possible to expose and eliminate hidden defects in the machines.

Multidisciplinary teams

Everyone, from operator to maintenance engineer, should make joint efforts to improve the OEE. This can be achieved by forming small multidisciplinary teams.

This can be achieved by giving attention to autonomous maintenance, preventive maintenance, training of the employees involved, security and standardization of work processes, the goal is Zero Defects: zero errors, zero losses and zero work-related accidents.

By using such multidisciplinary teams, the availability of machines will improve greatly. TPM focuses on the effective and efficient use of production means and aims at involvement of all departments.

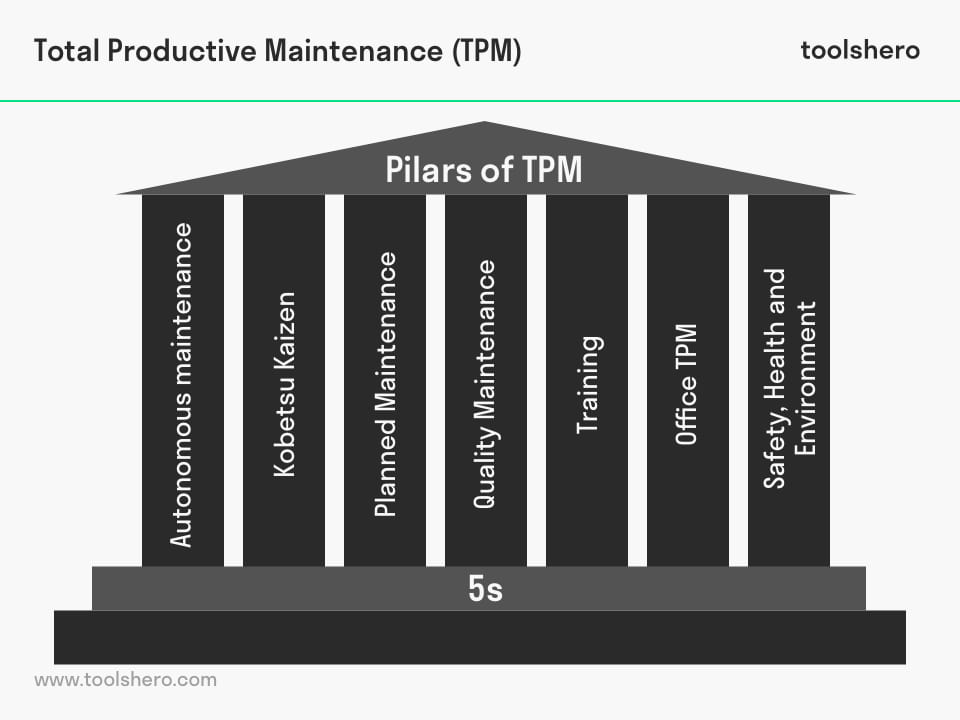

The small multidisciplinary teams work together from seven different TPM pillars, supported by 5S, to improve equipment reliability and increase productivity.

These basic seven pillars are:

- Autonomous maintenance

- Kobetsu Kaizen (Focused Improvement)

- Planned Maintenance

- Quality maintenance

- Training and Education

- Office TPM

- Safety Health Environment (SHE)

Continuous improvement

TPM will improve productivity by 70% and reduce complaints by approximately 60%. In addition to measuring OEE, TPM also focuses on maintenance backlog which is also referred to as Total Clean Out (TCO). After this, a start can be made with the continuous improvement cycles.

Each multidisciplinary team tackles one specific problem that limits the OEE, therefore the continuous improvement cycle can be carried out very effectively. The project that this small team carries out is called Small Group Activity (SGA).

In such a SGA project team there are both machine operators and mechanics as well as quality inspectors and logistics managers. The whole group is responsible for the functioning of a specific machine.

Perfection

Like other process improvement methods, TPM has grown into a general process management method, which can be applied broadly to strive for machine perfection. In addition to machine availability, other factors play a role such as logistical and human aspects.

Therefore, the strong involvement of employees across different disciplines forms an important part of TPM. Everyone is involved from start to finish. This makes TPM a useful method that monitors complex and/or expensive machines; it prevents maintenance costs from becoming too high and it ensures that production does not stagnate.

It’s Your Turn

What do you think? Is Total Productive Maintenance (TPM) still applicable in today’s business companies? And if so, how do you use it and what are the general results and learning lessons? Is the basics theory the same or are there new ones?

Share your experience and knowledge in the comments box below.

More information

- McKone, K. E., Schroeder, R. G., & Cua, K. O. (2001). The impact of total productive maintenance practices on manufacturing performance. Journal of operations management, 19(1), 39-58.

- Nakajima, S. (1988). Introduction to TPM: Total Productive Maintenance. Productivity Press, Inc.

- Wireman, T. (2004). Total Productive Maintenance. Industrial Press.

How to cite this article:

Mulder, P. (2016). Total Productive Maintenance (TPM). Retrieved [insert date] from Toolshero: https://www.toolshero.com/quality-management/tpm-total-productive-maintenance/

Add a link to this page on your website:

<a href=”https://www.toolshero.com/quality-management/tpm-total-productive-maintenance/”>Toolshero: Total Productive Maintenance (TPM)</a>