Carter’s 10 Cs of Supplier Evaluation

Carter’s 10 Cs of Supplier Evaluation: this article provides a practical explanation of Carter’s 10 Cs of Supplier Evaluation. After reading, you’ll understand the basics of this powerful Supplier Evaluation method.

What are the Carter’s 10 Cs of Supplier Evaluation?

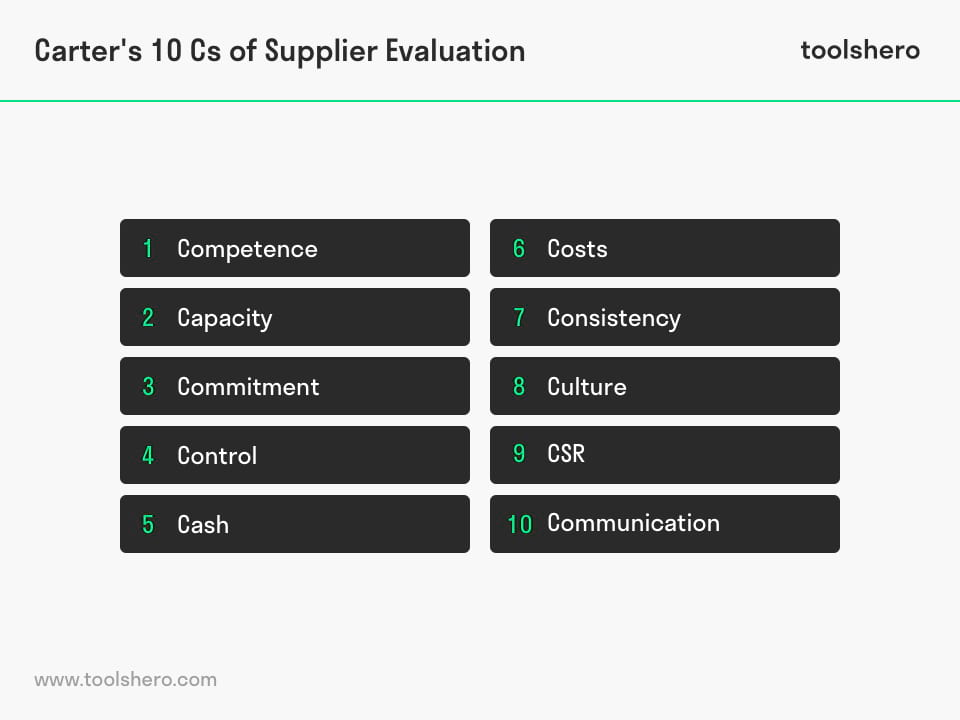

The Carter’s 10 Cs of supplier evaluation method gets its name from Ray Carter, director of DPSS Consultants. He had originally described the 7 Cs of effective supplier evaluation in a 1995 article in ‘Purchasing and Supply Management‘. That number has become 10 since then. They offer a clear focus for anyone involved with selecting or evaluating suppliers.

It’s important to sketch out the needs of an organisation. It’s even more important to understand how suppliers can meet those needs in order to find the right one. That evaluation can be carried out by visiting the suppliers’ websites or analysing questionnaires and interviews. You can also assess it by looking at quality standards, financial stability, organisational structure, etc.

The model consists of 10 core criteria. Together they ensure that the decision that is taken carries the lowest risk and is the most optimal one.

Why Carter’s 10 Cs of Supplier Evaluation?

In order to add a supplier to the approved supplier list (ASL), an organisation looks to both existing and potential suppliers. After all, they compete with each other in several ways and that can help improve the performance of existing suppliers. This helps you to have the right list of approved suppliers when you need it.

Research has shown that most supplier problems are caused by the lack of a thorough supplier and contractor selection and evaluation process. In addition, it’s also known that ineffective work environments and poor training management after granting a supplier contract can contribute to suboptimal performance.

The importance of supplier evaluation in business

Supplier evaluation increases the visibility of performance

When businesses don’t know the fact about their suppliers, their supplier management tends to be largely based on guesswork. Evaluating suppliers helps improve performance and achieve organisational objectives, also improving the visibility of that performance.

Reduce risk

Insight into supplier performance and business practices helps to reduce risks. Those risks can be financial in nature or operational.

Coordinating customer and supplier practices

The supplier has to run their business based on their clients. They can share similar business ethics and have similar quality standards and show continuously available improvement.

Getting started with Carter’s 10 Cs of Supplier Evaluation

Using the following 10 Cs, you can evaluate and select suppliers.

1. Competence

Does the supplier have the skills to get you what you need? You start by looking at how competent the supplier is by thoroughly assessing them. You then compare what you’ve learned to your needs. Don’t forget to check what their other clients think. How have they experienced working with this supplier?

2. Capacity

Does the supplier have sufficient capacity (equipment, staff, and materials) to meet your business’s needs? Can the supplier adjust their capacity to those needs? According tot the 10 Cs of Supplier Evaluation it’s important that the supplier has sufficient capacity to be able to offer what you require. Meaning how quickly will the supplier be able to respond to that and other market and supply fluctuations?

3. Commitment

Quality is an important prerequisite for any business – is the supplier committed to maintain the right level of quality performance?

Is the supplier actively working to ensure high quality standards? Examples of that could be quality initiatives within their organisation, for instance based on ISO 9001 and Six Sigma.

4. Control

Is the supplier in control of their policy and procedures? Can they ensure that their performance is consistent? Ask how well this supplier is in control of their policy, processes, procedures, and supply chain.

5. Cash

Does the supplier have sufficient financial reserves? The supplier has to be strong financially. That’s because cash-positive businesses are in a much better position to handle any economic turmoil.

6. Costs

What do the supplier’s products cost. And how do those product costs compare to other suppliers you might be considering?

7. Consistency

Does the supplier deliver a consistent product? According to the 10 Cs of Supplier Evaluation, the supplier has to have processes or procedures that help safeguard consistency. Ask for a test product.

8. Culture

Does the supplier share the same cultural values as your organisation? Is it important that the supplier shares the same values and attitudes to help prevent any tensions in the future relationship? A good partnership usually involves two companies observing the same values. That’s why it’s important to consider the supplier’s corporate culture.

9. CSR

Does the supplier have a suitable sustainability policy? To what extent does the supplier make an effort to comply with environmental regulations? Also look into how the supplier treats people, both its own and those in its environment.

10. Communication

What tools can you use to communicate with the supplier? Do they have regular people for communication? Ask them how they plan to stay in touch. Do the proposed approaches to communication match those that you prefer?

Glossary

Supplier

A supplier delivers goods or services in exchange for money. A supplier can supply companies and retail businesses and can be a wholesaler or a manufacturer. The party who purchases goods or services from a supplier is also called a client or customer.

Supplier selection

The phase in the procurement process when the potential client chooses the supplier they prefer and is most suitable.

Meetings

A personal discussion can help to clarify specifications and determine whether a supplier can meet the requirements of a complicated procurement.

Website visits

While many suppliers look good on paper, a visit to their website can help determine if there are any inefficiencies.

Third-party evaluators

Certain organisations can be engaged to thoroughly evaluate and check potential suppliers.

- Requires trained staff

- Involves surveys

Now it’s your turn

What do you think? Are you familiar with Carter’s 10 Cs of Supplier Evaluation or do you have anything to add to this explanation? When do you think this supplier evaluation model can be effective? What do you believe are success factors that contribute to the practical application of this theory?

Share your experience and knowledge in the comments box below.

More information

- Carter, R. J., Kirby, S. K., & Jackson, P. (2014). Practical procurement. Cambridge Academic.

- Ho, W., Xu, X., & Dey, P. K. (2010). Multi-criteria decision making approaches for supplier evaluation and selection: A literature review. European Journal of operational research, 202(1), 16-24.

How to cite this article:

Sari, J. (2019). Carter’s 10 Cs of Supplier Evaluation. Retrieved [insert date] from Toolshero: https://www.toolshero.com/strategy/carters-10-cs-of-supplier-evaluation/

Published on: 06/13/2019 | Last update: 05/19/2022

Add a link to this page on your website:

<a href=”https://www.toolshero.com/strategy/carters-10-cs-of-supplier-evaluation/”>Toolshero: Carter’s 10 Cs of Supplier Evaluation</a>