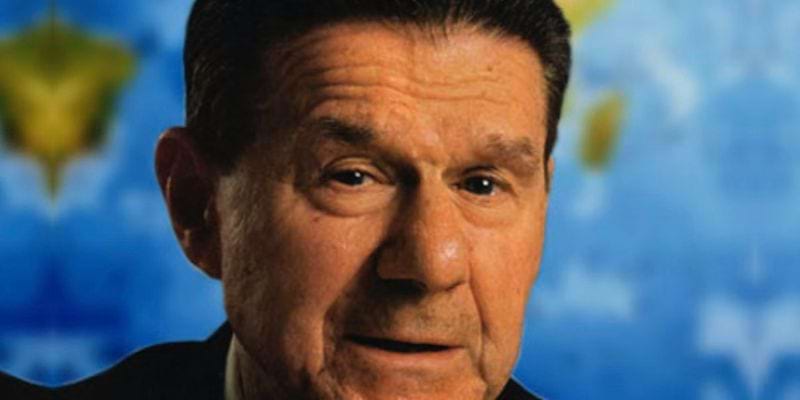

Armand Feigenbaum biography, quotes and books

Armand Feigenbaum (Armand V. Feigenbaum; 6 April 1922, 10 November 2014) was an American quality expert, businessman, and philanthropist who introduced the concept Total Quality Control what eventually led to Total Quality Management (TQM). He additionally authored the well-known book Total Quality Control: Principles Practice and Administration, a book that integrates an organization’s quality development, manufacturing operations, quality and cost with existing business practices to produce quantifiable customer satisfaction. The book is translated into more than 20 languages and it covers Armand Feigenbaum ’s ideas that are derived from his earlier articles. Armand Feigenbaum furthermore co-authored The Power of Management Capital, a book that set a new direction for innovation in management in the twenty century.

The biography of Armand Feigenbaum

Armand Feigenbaum was born in New York City. He started to work when he approximately 12 years old at General Electric as a pre-college job. In this time, he grew within the company from an apprentice toolmaker to a management intern with the turbine, engine, and transformer group.

Feigenbaum was sixteen when he went to Union College in New York. He studied engineering while he simultaneously worked at General Electric. His work in school mainly focused on mathematics, statistics, engineering, and economics.

Feigenbaum graduated in 1943, and because of this, he developed in the company to work as a fulltime design engineer. The Union College honored Armand Feigenbaum and his brother for their generosity, and consequently, named the school administration building after them.

Pretty soon during his professional development at General Electric, he got promoted to manager of quality control and he worked for the Schenectady Works Plant in New York. Even though he got promoted, Feigenbaum was ambitious and continued his studies by following a Master’s and Ph.D. at graduate school at Massachusetts Institute of Technology.

Consequently, he got promoted again. This time, Arman Feigenbaum worked as a director of the operations and quality control at General Electric’s headquarters in New York City. While he worked for General Electric, Armand developed the Total Quality Control concept.

contribution to Quality Management

According to Feigenbaum, total quality control is crucial achieve productivity, market penetration, and competitive advantage. He puts customers first to identify their needs and wants and then create the product or service to satisfy the customer. He also believed that the level of quality determines organization’s success and growth.

Feigenbaum continued his research. By 1968, he established General Systems Company (GSC), an international consultancy and technical service provider, together with his brother Donald S. Feigenbaum to further research technology management. He worked with Toshiba and Hitachi, and by this time, Feigenbaum traveled around the world.

Both he and his brother share history in providing philanthropic work. The brothers funded various organizations, but at one day, they decided to establish the Feigenbaum Foundation, an organization dedicated to improving the quality of life in the Berkshires. The organization has also taken over other organizations they funded before.

They established the Feigenbaum Hall of Innovation at the Berkshire Museum, which shows innovators and inventions that originated in the Berkshires and transformed the world.

They funded projects regarding environmental protection but also projects related to education and culture to improve the quality of life of people.

Next to this, Armand Feigenbaum was president of the American Society for Quality and of the International Academy for Quality. He furthermore received various awards and recognitions such as the Distinguished Leadership Award by the Quality & Productivity Management Association.

In 1988, dr Feigenbaum was also appointed by the Secretary of Commerce in Washington D.C. to the first Board of Overseers of the Malcolm Baldrige National Quality Award Program.

He received the Edward Medal of the American Society for Quality for his outstanding leadership in the field of quality control. Feigenbaum additionally received an honorary doctor of science degree from the College in 1992, and the Alumni Gold Medal in 2012.

In 1996, Feigenbaum received the Ishikawa/ Harrington Medal by the Asia-Pacific Quality Organization for his outstanding leadership in management excellence in the Asia-Pacific Region. In 2008, he was presented with the National Medal of Technology and Innovation, the highest honor for technological achievement bestowed on America’s leading innovators, by President Bush.

Many other awards and honors have been given to Armand Feigenbaum for his contributions to quality control bacause of influenced management strategy and productivity in the competition for world markets in the United States, Europe, Asia, Latin America and the Middle East.

His name is the today’s synonym for total quality control and total quality management.

Famous quotes

- “Total quality control is an effective system for integrating the quality development, quality maintenance, and quality improvement efforts of the various groups in an organization so as to enable production and service at the most economical levels which allow full customer satisfaction.”

- “Pursuing excellence, deep recognition that what you are doing is right, is the strongest motivation in any organization and is the main driver for true leadership qualities.”

- “Quality is the total composite product and service characteristic of marketing, engineering, manufacturing, and maintenance through which the product and service in use will meet the expectations of the customer.”

- “An important feature of a good quality program is that it controls quality at the source.”

Publications and Books of Armand Feigenbaum et al.

- 2009. The Power of Management Innovation: 24 Keys for Accelerating Profitability and Growth. McGraw-Hill, Inc.

- 2008. Raising the bar. Quality Progress, 41(7), 22-27.

- 2005. What quality means today: leadership and management innovation must drive a comprehensive ethos of excellence. MIT Sloan Management Review, 46(2), 96-97.

- 2005. Total quality control: Achieving productivity, market penetration and advantage in the global economy. McGraw-Hill Higher Education.

- 2002. The power behind consumer buying and productivity. Quality Progress, 35(4), 49.

- 2001. How to manage for quality in today’s economy. Quality Progress, 34(5), 26-26.

- 1999. The new quality for the twenty-first century. The TQM magazine, 11(6), 376-383.

- 1998. The future of quality management. Quality Digest, 18, 33-38.

- 1997. No pain, no gain. CHIEF EXECUTIVE-NEW YORK-, 36-39.

- 1997. Changing concepts and management of quality worldwide. Quality progress, 30(12), 45.

- 1996. Managing for tomorrow’s competitiveness today. The Journal for Quality and Participation, 19(2), 10.

- 1994. Quality education and America’s competitiveness. Quality progress, 27(9), 83.

- 1994. How total quality counters three forces of international competitiveness. Global Business and Organizational Excellence, 13(3), 327-330.

- 1993. We can’t improve American quality if we aren’t teaching it. National Productivity Review, 12(2), 139-142.

- 1993. Managing improvement in the US government. Global Business and Organizational Excellence, 13(1), 7-10.

- 1990. America on the threshold of quality. Quality, 29(1), 16.

- 1989. Seven Keys to constant quality. Journal of quality and participation, 12(1), 20-23.

- 1989. How to implement total quality control. Executive Excellence, 6(11), 15-16.

- 1988. In Quality the Key Word Is Total: Genuine Quality Improvement. Journal for Quality and Participation, 11(1).

- 1983. Total quality control.

- 1977. Quality and productivity. Quality Progress, 10(11), 18-21.

- 1961. Total quality control: engineering and management, the technical and managerial field for improving product quality, including its reliability, and for reducing operating cost and losses(No. TS156. Q3 F45).

- 1956. Total quality-control. Harvard business review, 34(6), 93-101.

- 1951. Quality control: Principles, practice and administration: An industrial management tool for improving product quality and design and for reducing operating costs and losses. McGraw-Hill.

How to cite this article:

Zeeman, A. (2018). Armand Feigenbaum. Retrieved [insert date] from Toolshero: https://www.toolshero.com/toolsheroes/armand-feigenbaum/

Original publication date: 06/08/2018 | Last update: 01/12/2024

Add a link to this page on your website:

<a href=” https://www.toolshero.com/toolsheroes/armand-feigenbaum/”> Toolshero: Armand Feigenbaum</a>