Gemba walk

Gemba walk: this articles provides a practical explanation of Gemba and the Gemba walk. After reading, you’ll have a basic understanding of this powerful quality management tool. In this article you will also find a downloadable Gemba walk checklist to get you started right away.

A popular phrase in Lean management is: “Go to the Gemba”. What’s meant by it and how to make good use of it in your organization and situation. In this article the deeper meaning of Gemba will be explained as well as a useful checklist and tips to overcome potential pitfalls.

Definition and use

Gemba literally means in Japanese: “The exact location”. In organizations this exact location means the shopfloor, the place where the added value is created. In a lot of cases this means the production floor, but in case of service organizations, this can also be the office floor where the people deliver their services.

Gemba or Genba

In this article I’ll use the word Gemba, while I know that according to language specialists the translation is GENBA. In the pronouciation, when litterally translating the Japanese word, however it is heard as Gemba in English. That’s the reason that Gemba is more commonly used and why I use Gemba in the rest of the article.

Why Gemba?

Gemba is a lean management technique, which, as many of the LEAN techniques originates from The Toyota Production System. The philosophy d it is that you will only make the right steps and improvements when you see how it works.

In a lot of organizations, working instructions, task instructions are described and training is given to the employees. In practice, however, the instructed way of working is not always the daily practice.

This is one of the main reasons that leaders shouldn’t assume they know how people work, but they should go and walk the floor. Instead of talking about it from a conference room, seeing it with your own eyes brings a lot more clarity on how things actually are.

This principle is in fact similar to the principle of Management By Walking Around (MBWA). In the practice of Lean and Six Sigma, it means taking the time to observe the business processes and discuss them with those involved.

Are the employees than crossing a line, by not adhering to the instructions? That could be the case, but it’s more important to understand why people are not following the instructions. Gemba walks can also be initiatied for other problem solving purposes, depending on the intent of a given walk.

Are the instructions wrong, are they not clear, did people find a better way or did they simply forgot how it should be. The Gemba walk is definitely not meant to give people a warning when not following the rules, it’s the opportunity to improve processes and develop your people at the front line. Futhermore, it gives the management a fresh perspective of what is really happening in the workplace.

When you read this as a leader in an organization and you think this is not happening in your department than I recommend “Genchi Genbutsu”; go and see yourself.

Gemba checklist for leaders

All leaders should be in continuous contact with the people that create the added value. In practice it’s clear that there are different levels of leadership and as such you might also say a different routine for a Gemba checklist.

I make a clear distinction between a Gemba checklist for senior management and line management. Simple reason is that in bigger organizations it’s simply not possible that the CEO is in day-to-day contact with all people and it’s also not desirable as he needs to be working on the vision, whereby he needs to keep the contact, for which Gemba can be used.

For all leaders it should be clear that the interest is sincere and authentic, always! People will surely feel it when it’s not and than the damage in mutual trust is bigger than the gain in knowing what’s going on.

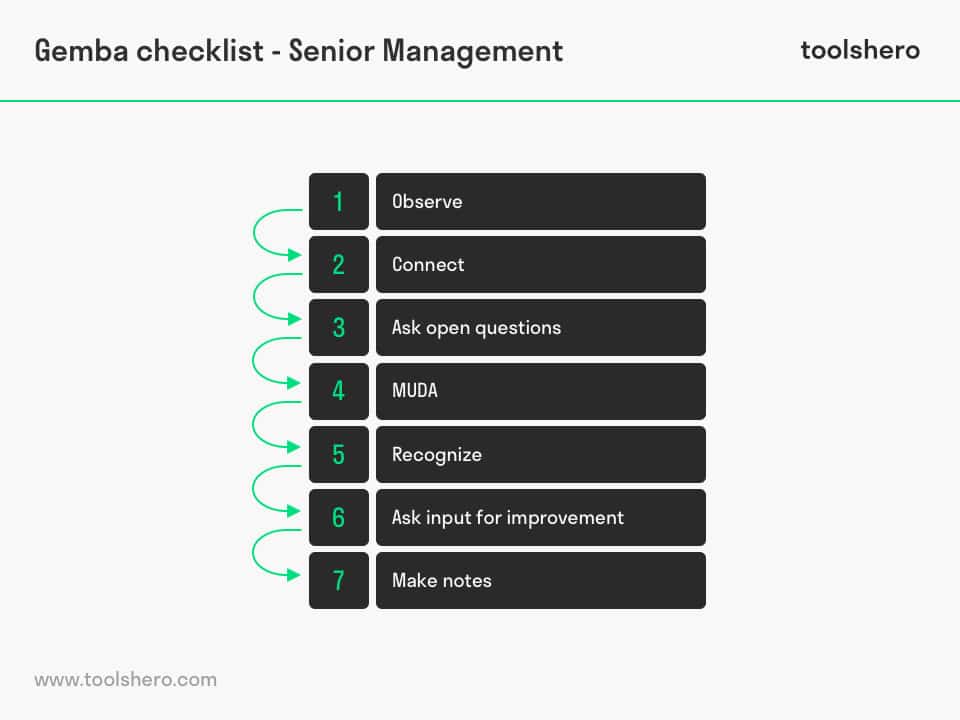

Gemba checklist – Senior Management

Desired frequency: 1 Gemba walk per day

Meant for: Level C – leaders that have more than 3 other leaders reporting to them.

1. Observe

Observe the situation and see what’s really happening. How do people act and work. How do they process their tasks and make sure quality is assured.

2. Connect

Don’t assume that by just observing you know what’s good and what’s bad. Get in contact with the observed person and tell them you’re interested and want to know more. Be clear that you want to learn.

3. Ask open questions

People in general are keen and proud on their work and achievements. Typical place to ask questions is the Gemba Walk Board.

4. MUDA

There are 8 types of ‘waste’ or MUDA defined in Lean management. Use these 8 types to identify waste spillages at the shopfloor. It’s considered the basis for business process improvements. This is an iterative process, meaning continuous improvement when executed frequently.

5. Recognize

Give team members the recognition that they do make the difference and make, when possible, a sincere compliment. Show them appreciation for the work that is being performed.

6. Ask input for improvement

Be open and clear, but don’t make the decisions on the spot, unless the line leader is part of the Gemba walk. Make sure you don’t overrule the line leaders as you want to empower them as well.

7. Make notes

Make sure you write down the attention points given by the employees. Worst thing what can happen, is that you acknowledge their good thoughts and they never hear anything from it anymore.

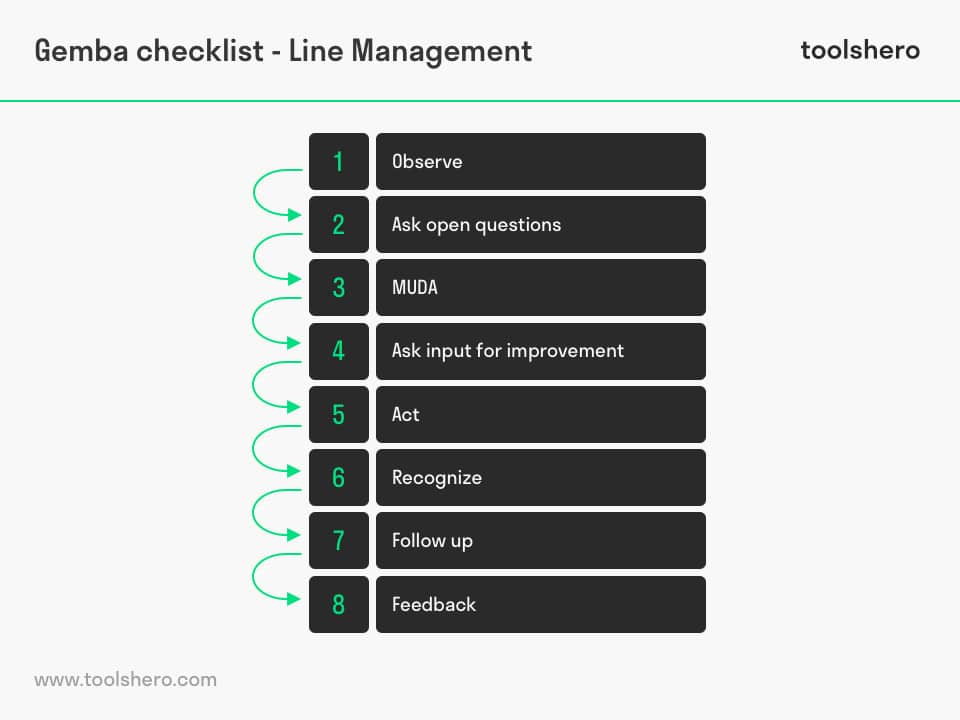

Gemba checklist – Line Management

Desired frequency: Throughout the day, as much as possible

Meant for: Line leaders that have more less than 3 other leaders reporting to them.

1. Observe

Observe the situation and see what’s really happening. How do people act and work. How do they process their tasks and make sure quality is assured.

2. Ask open questions

People in general are keen and proud on their work and achievements. Typical place to ask questions is the Gemba Walk Board, also make sure that their adherence to Standard Operating Procedures is being checked.

3. MUDA

There are 8 types of ‘waste’ or MUDA defined in Lean management. Use these 8 types to identify waste spillages at the shopfloor. It’s considered the basis for process improvements

4. Ask input for improvement

The best solution is the solution which came up together with the employees.

5. Act

When a deviation is seen or a possibility to improve is seen and can be picked up immediately, do it. Act and make the next steps.

6. Recognize

Make sure you recognize the input given by the employees.

7. Follow up

When bigger deviations or improvements which can’t be solved immediately arise, make sure there’s a proper follow up.

8. Feedback

Make sure that you always give the employees feedback on their input. Also when it turns out that the idea is not pursued, explain them why.

Gemba walk checklist (line management)

Get started with Gemba Walks and use this checklist as a practical tool to go through the steps and take notes.

Download the Gemba walk checklist

This template is exclusively for our paying Toolshero members. Click here to see if a membership is something for you!Gemba Walk Board

The Gemba walk board is the place where the department gives an insight on their performance, open issues and goals to pursue. As such, it gives focus on the desired goals and clear direction, which should be in line with the vision and goals of the overall organization.

The Gemba walk board has a specific setup, but is however not exactly the same for every organization. For a production environment it should however always start with Safety. In general the setup of a Gemba Walk Board is:

Safety

Safe in and safe out should be the motto for every (production) organization. As such it’s key to have clear insight on safety progress (KPI’s), safety measures and improvements.

Quality

Quality will define the success of your future. Without the desired quality and consistency, your customer will eventually go to a competitor. Here, also the insight (KPI’s) should be visible, as well as CAPA (Corrective Action Preventive Action).

When an inconsistency was found, it should be clear what was done to overcome the inconsistency. This could also be the basis for the Gemba walk to adjust existing Operating Procedures.

Performance/Productivity

An organization can have 0 LTI’s, 0 quality complaints, but without quantity and performance this is not sufficient to keep the business running. As such it’s important to see in a glance how the performance is and which problems occurred.

Morale

This particular pillar is gaining interest in more organizations and actually becomes part of the standard. This pillar should show whether the people in the organization are motivated.

An organization can have excellent processes in place, but at the end of the day the difference between an OK performing and an Excellent performing company are people. To make this particular pillar SMART is very challenging. It’s not based on exact, computable numbers, but more based upon the feelings of the people working at the organization.

Others

In example: Costs, Illness rate or number of improvements. Depending on the challenges of the particular organization the additional focus can be measured and shown on the Gemba Walk Board. Make however sure that you don’t put too many pillars on the board as that could create an overkill and lack of focus.

Pitfalls and tips

When introducing and starting a Gemba in an organization which is not yet used to work like this, you might find some resistance and potential pitfalls. In this part I’d like to highlight most common pitfalls and tips to overcome:

Employees who do not like observation

Employees which are being observed and who are not used to that, don’t like that. They will not trust the situation and might even think that it’s a mission from management to give them a hard time.

Explain what you’re doing and why you are doing it. Above all, make sure you don’t judge nor tell the employees what to do or that they’re doing something wrong. Follow the mentioned checklist and above all, be sincere and honest.

Jumping into conclusions and actions immediately

One of the biggest pitfalls for leaders is to jump into conclusions and actions immediately. Most of the leaders became a leader, because of their action-oriented character, combined with a good set of knowledge.

Postpone your judgement and enjoy the fact that you’re developing people by asking, questioning and to improve together with the people. As a leader, the best thing what can happen is that people themselves come up with good ideas, after you asking why things are done in a certain manner. Take pride out of that, in stead of taking pride of being the one that comes up with all solutions.

Implementing new techniques too rigid

Lean leaders and lean gurus tend to implement new lean techniques too rigid from the beginning. A precise way of working and checklists are made as well as training how to do what in which way. This could undermine the deeper meaning of Gemba.

You can loose the connection with the employees and make the model or checklist the most important part. Than you know you are too rigid and the technique is implemented perfectly, but the bigger goal is completely missed.

As a leaders, use the techniques and follow the steps, but make it your own and make sure you do it in a way it suits you best. The bigger goal is to improve processes and developing people in a structured way. Use it to achieve that objective. Don’t make the tool the goal of the process.

No time

Leaders claim they have no time in their agenda to be on the shop floor. This is a much heard sentence and especially used by Level C leaders. Please reconsider your prioritiess, because who is adding the value and making the difference, your meetings or the people on the shopfloor?

It could help to just block time in your agenda. Make it recurrent and important. Don’t let it be overbooked by another meeting and make that clear to everyone in the organization.

How to start

As a leader, how to start with Gemba walks? A big brand might say: Just get started. Walk through the mentioned checklist and look for additional information on the internet. Of course, a training could help you further, but in the basis all leaders are capable of making Gemba walks.

Setting up a Gemba walk board, making clear overviews will take more time and might involve support from other colleagues or consultants. The essence, however can be done as of today. Every leader can start right now.

Now it’s your turn

What do you think? Are you familiar with the explanation of Gemba and Gemba walks? Does your organization use the Gemba walk board? Do you have any other tips or additional comments?

Share your experience and knowledge in the comments box below.

More information

- CSS Editorial Staff. (2016, June 28). Gemba Training and Research Page. Retrieved from https://www.creativesafetysupply.com/articles/gemba/

- FMDS Gemba Walk. (2016). [Videobestand]. YouTube. Retrieved from https://www.youtube.com/watch?v=rWIHoYUoiTE

- Gemba. (2019, 21 oktober). Geraadpleegd van https://www.lean-6-sigma.nl/gemba-walk/

- TEDx Talks. (2013, June 17). Go to the Gemba: Deborah Adler at TEDxRVA 2013 [Video file]. YouTube. Retrieved from https://www.youtube.com/watch?v=A_DGAGzyPEg

- Womack, J. (2013). Gemba Walks: Expanded 2nd Edition. Lean Enterprise Institute.

How to cite this article:

Huijgens, P. (2020). Gemba walk. Retrieved [insert date] from Toolshero: https://www.toolshero.com/quality-management/gemba-walk/

Add a link to this page on your website:

<a href=”https://www.toolshero.com/quality-management/gemba-walk/”>Toolshero: Gemba walk</a>