HACCP plan explained

HACCP plan: this article explains the HACCP plan in a practical way. The article starts with a general definition and meaning of HACCP, followed by an extensive step-by-step plan and finally you will find information about risks and controls associated with HACCP. You will also find a practical example of a fictional company who follows the HACCP process to ensure food safety. Enjoy reading!

What is HACCP?

HACCP stands for

HACCP stands for Hazard Analysis and Critical Control Points and is aimed at risk assessment for food products. That makes it a system for food safety. The HACCP system originated in American space exploration.

In the 1960s, NASA came up with it as a way to inspect astronaut food. It was an important mission to come up with ways to send food up for extended periods of time, without risking food poisoning from it becoming spoiled.

Preventive

HACCP is a preventive system and is part of European legislation. All organisations that are involved with the preparation, processing, treating, packaging, transporting and distribution of food are confronted with the HAACP standards.

It concerns a variety of sectors, including the hospitality industry, food industry and logistics, food wholesalers and retailers such as supermarkets. The HACCP standard is meant to ensure that the entire production process of food products is done with care, reducing the risk of contamination or spoiling to a minimum.

When processing food products, it’s possible for mistakes or mishaps to occur that could endanger food safety. That’s why businesses have to determine what can go wrong for each stage of production, and how they can prevent those things. The potential risks have to be described in a food safety plan; the HACCP plan.

Health Hazards

A health hazard is a danger that might be present in food production and that can then become a threat to consumer health. By identifying and then managing health hazards in preparation and processing processes, you increase the safety of the product. Examples are:

- Microbiological hazards such as bacteria, moulds, viruses and parasites that can contaminate food and lead to serious infection after ingestion.

- Chemical hazards as a result of harmful substances such as dioxins, heavy metals, antifungals and pesticides.

- Physical hazards including sharp particles made of metal, wood, bone, or glass or other splinters that can threaten people’s health.

Potential Risks

Analysis refers to analysing the potential presence of hazards. Companies have to first assess potential risks. The risk is a combination of the likelihood of the danger and the seriousness of the effects on consumer health if it were to occur. Critical Control Points are points in the process that have to be managed in order to prevent any hazards, or to reduce them to acceptable levels.

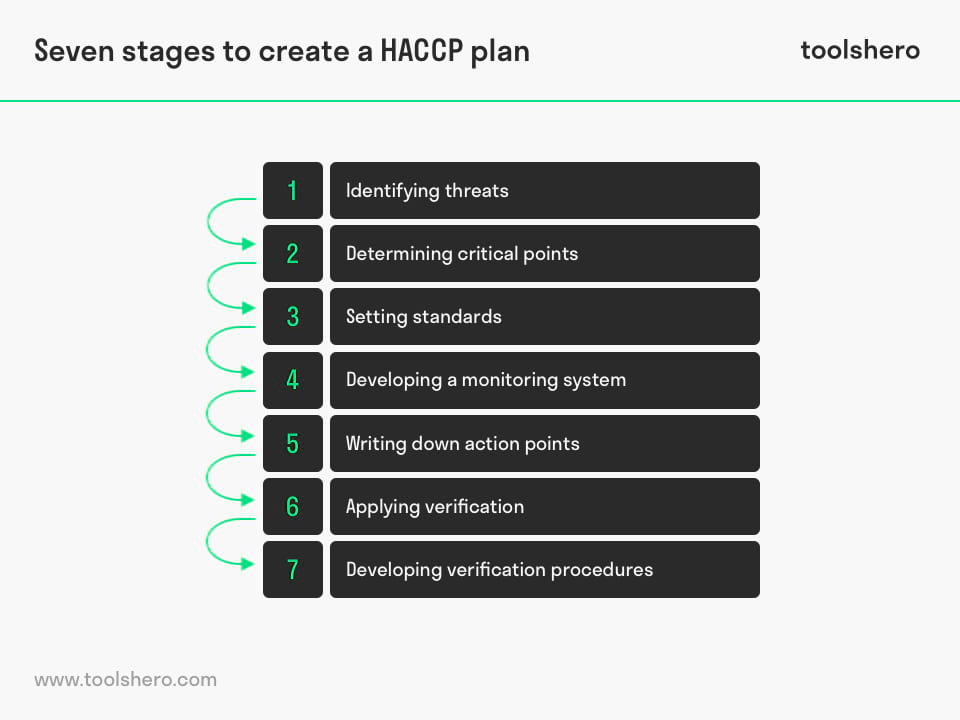

Seven Stages for a HACCP plan

The HACCP plan is based on seven stages. Each company has to interpret and apply these themselves. Companies indicate themselves where and in what stage of the production and distribution risks to the health of consumers might arise.

Companies come up with a food safety plan using approved hygiene codes. The HACCP plan also describes what measures businesses should take to prevent risks to the health of consumers, which checks need to be carried out and what the results are. What follows is a step-by-step description of what businesses need to do to create a proper HACCP plan.

Figure 1 – Stages of a HACCP plan

Stage 1: identifying threats

Each HACCP plan starts with a list of potential dangers in terms of food safety. Possible dangers of the processes carried out within the company that can occur on a (micro-)biological, chemical, physical and biotechnological level. Each company and each industry has its own dangers and risks. It’s also necessary to first estimate the likelihood of the danger actually occurring and how serious the damage would be if it did.

Stage 2: determining critical points

The so-called critical control points (CCPs) indicate where in the process the risk can be prevented or reduced. These points need to be monitored to prevent any dangers to food safety. This involves common hygiene measures or process steps that are crucial to food safety.

Stage 3: setting standards

By setting a standard for each critical control point, it becomes clear when a potential risk is acceptable and allowable. Applicable laws will always have to be taken into account when setting those standards.

Stage 4: developing a monitoring system

By laying out how the control points have to be monitored and checked, all the parties involved know what is expected of them. Developing a monitoring system makes it possible to properly follow procedures and more easily achieve the goal. This shows in concrete methods and actions.

Stage 5: writing down action points

By writing down corrective measures for each control point, it becomes clear what actions are required when it is established that a CCP does not meet the standards that have been set or when risk limits are exceeded. These actions mainly consist of preventive measures to prevent repeats and to ensure that consumers are involved with risks as little as possible.

Stage 6: applying verification

A periodic check to verify if the HACCP approach is working properly ensures strict monitoring of methods and safety. By writing down procedures, all the information regarding methods, purchasing procedures and measures becomes clear.

Stage 7 of the HACCP plan: developing verification procedures

Without documentation and registration, it’s impossible to apply verification (stage 6). Verification is necessary to check whether procedures help to safeguard food safety. Think of inspecting food products and work methods and documenting the results.

Example HACCP FreshTomato

Consider the following example about the company FreshTomato. The company produces and sells fresh tomatoes in various salads and other meals.

HACCP Phase 1

FreshTomato conducts a detailed inventory of potential hazards to food safety. They identify microbiological risks such as Salmonella, chemical risks such as pesticide residues, and risks such as allergens.

HACCP Phase 2

After identifying the hazards, FreshTomato determines the critical control points (CCPs) in their process. They identify crucial steps such as washing vegetables, monitoring the temperature during storage, and packaging the products under hygienic conditions as CCPs.

HACCP Phase 3

FreshTomato establishes standards for each critical control point. For example, they determine that the temperature during storage should always remain below 4 degrees Celsius to prevent microbial growth.

HACCP Phase 4

The company develops a control system that includes regular checks and monitoring of the critical control points. They implement procedures for recording temperature measurements, inspecting the hygiene of production equipment, and following cleaning protocols.

HACCP Phase 5

FreshTomato establishes action points for each CCP. For instance, if the temperature exceeds 4 degrees Celsius, a corrective measure is implemented, such as immediately cooling the products and investigating the cause of the temperature breach.

HACCP Phase 6

The company applies regular verification through internal audits and inspections. They ensure that the HACCP procedures are followed correctly and food safety is ensured.

HACCP Phase 7

Finally, FreshTomato develops verification procedures in which all checks, inspections, and results are documented and recorded. They maintain accurate records of temperature measurements, cleaning activities, and microbiological tests to demonstrate the effectiveness of their HACCP system during external audits.

HACCP monitoring

In the Netherlands, the Netherlands Food and Consumer Product Safety Authority (NVWA) is the organisation that monitors if businesses comply with HACCP standards and hygiene regulations.

In order to ensure a safe food production process, all food companies and animal feed companies have to implement a food safety system based on HACCP. One of the things the NVWA inspects is if businesses have and comply with an HACCP system. Different sectors use different hygiene codes.

Such a code serves as a guide for businesses that handle food and is created by the industry itself. The NVWA employs different hygiene codes for different sectors, including, dairy, care facilities, retail, hospitality, abattoirs, butchers and poulterers.

Summary

HACCP (Hazard Analysis and Critical Control Points) is a systematic approach used to ensure food safety throughout the entire food production process. The main goal of HACCP is to prevent, eliminate, or reduce potentially hazardous biological, chemical, and physical hazards to acceptable levels.

One of the key steps in implementing HACCP is to determine the critical control points (CCPs) in the process. These are specific points or steps in the production line where control measures can be applied to prevent or eliminate hazards or reduce them to acceptable levels. It is crucial to identify CCPs to ensure the safety of the finished product.

The HACCP team, consisting of individuals with relevant expertise and knowledge, plays a vital role in the implementation of the system. They are responsible for conducting a thorough analysis of potential hazards, establishing critical control points, and developing control measures.

Operating according to the HACCP plan is essential to maintain food safety worldwide. The plan outlines the specific steps and procedures to be followed at each critical control point to ensure the hazards are effectively controlled. Regular monitoring and documentation of these activities are necessary to verify that the system is functioning as intended.

The general principles of food hygiene form the foundation of HACCP. These principles include ensuring cleanliness, preventing cross-contamination, controlling temperature, and practicing good personal hygiene. By incorporating these principles into the HACCP system, food safety can be effectively maintained.

Monitoring is an important aspect of HACCP, but there are also other activities that determine the validity of the HACCP plan and the overall effectiveness of the system. These activities include conducting internal audits, reviewing documentation, and performing periodic reviews of the plan to ensure its continued suitability and effectiveness.

HACCP addresses various potentially hazardous hazards, including chemical and physical hazards. Chemical hazards can include contaminants, allergens, or food additives, while physical hazards refer to foreign objects such as metal fragments, glass, or plastic. Identifying and controlling these hazards at critical control points are crucial steps in ensuring the safety of the final product.

In summary, HACCP is a systematic and preventive approach to food safety that involves determining critical control points, preventing or reducing hazards, ensuring the safety of the finished product, and operating according to a well-defined plan. The involvement of a dedicated HACCP team, adherence to general principles of food hygiene, and thorough monitoring and verification activities contribute to the overall effectiveness of the system in controlling potentially hazardous chemical and physical hazards.

Now it’s your turn

What do you think? Do you recognize the practical explanation or do you have more additions? Is HACCP applied within your organisation? What are your thoughts on the HACCP plan?

Share your experience and knowledge in the comments box below.

More information

- Bauman, H. (1990). HACCP: Concept, development, and application. Food technology (USA).

- Mortimore, S., & Wallace, C. (2013). HACCP: A practical approach. Springer Science & Business Media.

- Pierson, M. D. (2012). HACCP: principles and applications. Springer Science & Business Media.

How to cite this article:

Mulder, P. (2019). HACCP plan. Retrieved [insert date] from Toolshero: https://www.toolshero.com/quality-management/haccp-plan/

Original publication date: 10/06/2019 | Last update: 04/08/2024

Add a link to this page on your website:

<a href=”https://www.toolshero.com/quality-management/haccp-plan/”>Toolshero: HACCP plan</a>