Zero Defects philosophy by Philip Crosby

Zero Defects philosophy: this article provides a practical explanation of the concept of Zero Defects by Philip Crosby. It covers what Zero Defects is and what its basic principles are. After reading, you will have a basic understanding of this quality management tool and philosophy. Enjoy reading!

What is Zero Defects?

Zero Defects refers to one of the concepts in the book ‘Absolutes of Quality Management‘ by Philip Crosby.

It is a management tool, a philosophy and is aimed at halting production defects through prevention. At the same time, it is also aimed at motivating and convincing people to identify and prevent mistakes by constantly encouraging them to perform their job well.

It is also a philosophy that asserts that the mistakes an employee makes are irrelevant. After all, these mistakes will be identified by inspectors before the product / service reaches customers. This philosophy focuses on conditioning the employee to ensure a personal interest serves as motivation in everything they do.

This is done by convincing the employee that his work is important for the success of the organisation. As mentioned, Philip Crosby is credited with developing this concept. He was a quality manager at the Pershing rocket programme of Martin Company.

Especially during the Cold War, Zero Defects gained a lot of traction. Eventually even NASA benefited from its Zero Defects operations.

For instance, reports on failed missile launches increased the pressure in achieving zero defects. The concept would later also be applied in the automotive industry. This resulted in drastic cost reductions and higher quality vehicles, especially in terms of safety.

Ultimately, a Zero Defects standard was created and implemented in many organisations around the world.

Defects Per Million Opportunities (DPMO)

Zero Defects is one of the concepts mentioned in the book ‘Absolutes of Quality Management‘. This highly regarded and popular concept is also addressed in the Six Sigma set of techniques.

Nevertheless, this theory and ‘Absolutes of Quality Management’ are also frequently criticised. For instance, people often state that production without defects is impossible.

Others reject this criticism by noting that literal perfection doesn’t exist in quality management, and that the principle only refers to an organisational state which eliminates waste and reduces the number of defects as much as possible. Zero Defects is about guaranteeing the highest possible quality standards in production and other projects.

The criticism that the production and execution of projects without defects is impossible is justified and true. According to the Six Sigma set of techniques, Zero Defects is defined as 3.4 Defects Per Million Opportunities (DPMO).

In this context, the Zero Defects concept must be regarded as a quest and strive for perfection, in order to improve and guarantee quality in the production process by using continuous improvement.

Perfection will never be achieved, but the invested energy will at least improve quality to a level that is acceptable, measured on the basis of strict measurement values and standards.

Fundamentals of Error Proofing: The Path Toward Zero Defects

Absolutes of Quality Management

Philip B. Crosby incorporated the idea of Zero Defects into the concept of ‘Absolutes of Quality Management‘. The idea was subsequently popularised by, among other things, implementing it into the employee training and quality procedures.

Many different articles, films, and speeches have been made about this philosophy. Not to mention, a Zero Defects day has even been organised in the past.

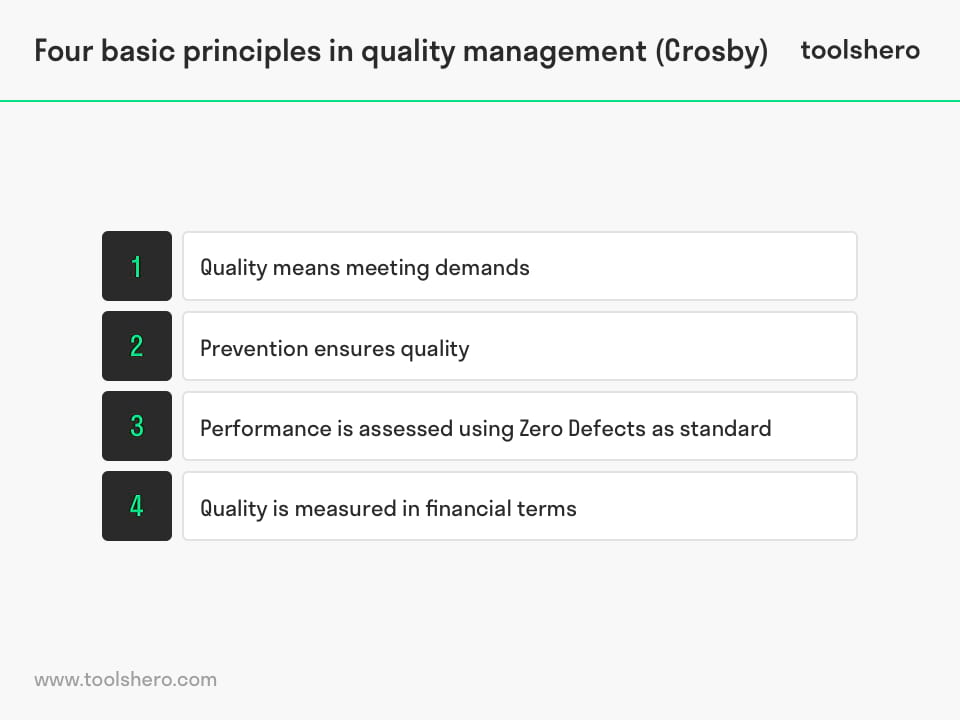

According to Philip Crosby, there are four basic principles of zero defects.

Figure 1 – Zero Defects Basic Principles (Crosby)

Quality Means Meeting Demands

The customer has certain demands, which the manufacturer must naturally meet. By participating in market research, the customer expresses his or her expectations of a project.

For example, the customer wants his TV to last for more than five years and doesn’t want his new roofing to start leaking after just three weeks. It is the responsibility of the organisation to meet customer expectations.

These customer expectations must be analysed in measurable amounts of information or properties, such as lifespan of a product, structure, form, etc.

Moreover, these quality requirements must be part of the production process. When an organisation meets requirements, quality is safeguarded. Zero Defects therefore also means that the requirements are met at all times.

An important concept here is DIRFT, or Do It Right The First Time. The secret behind DIRFT is to disclose conditions and requirements and not stand in the way of the employees.

Prevention Ensures Quality

If a problem with a product is identified when it is already in the hands of the customer, it’s too late. In this case, the defect has already occurred.

Here, prevention is about analysing and removing the cause of the problem. Companies often use inspections to ensure defect products do not reach the customers.

Nevertheless, there are cases where problems go unnoticed. Inspections are also time-consuming and costly. It is therefore important to safeguard quality from the very start.

Performance is Assessed Using Zero Defects as Standard

According to the concept behind this theory, Zero Defects should be the standard for all manufacturing. If not, it would become acceptable to produce products that are not up to standard.

In fact, as soon as it becomes normal not to strive for perfection, more and more defects will occur. Especially in the period following the Second World War, the lax attitude of employees proved to cause reduced quality. Crosby noticed this and started raising quality standards.

Quality is Measured in Financial Terms

The final principle of this philosophy is about the financial side of quality.

According to the model, quality, waste, product, and resources must be assessed from a financial perspective. There must be a quality measurement, where the price equals the cost of not meeting the customer’s requirements. These costs are the result of low quality.

The Zero Defects philosophy and senior management

Philip Crosby also emphasised that in order for a quality programme to succeed, senior management must be closely involved in quality control.

According to Crosby, it is the responsibility of the CEO to promote a culture of quality, in which quality improvement is always the highest priority.

To make this possible, management must provide the organisation and its members with everything they need to guarantee quality. As a fifth principle for quality management, this set of basic principles guarantees a ‘way of life’ when it comes to production.

When adhering to this strategy, the organisation will naturally reap the benefits. According to Crosby, the greatest effects of such a programme are reflected in a reduction of warranty costs, and improved customer satisfaction.

Now it’s your turn

What do you think? Are you familiar with the explanation of Zero Defects? Have you ever implemented Zero Defects or a different form of Six Sigma to prevent defects in a production process? What do you believe are the most important elements of quality management? Do you have any tips or additional comments?

Share your experience and knowledge in the comments box below.

More information

- Crosby, P. B. (1980). Quality is free: The art of making quality certain. Signet.

- Crosby, P. B. (1987). ” Absolutes of quality management” transfer from industry to health care. Health management quarterly: HMQ, 9(1), 3.

- Harkins, R. & Vellay, M. (2023). Fundamentals of Error Proofing: The Path Toward Zero Defects. Retrieved 01/07/2024 from Udemy.

- Schneiderman, A. M. (1986). Optimum quality costs and zero defects: are they contradictory concepts. Quality Progress, 19(11), 28-31.

How to cite this article:

Janse, B. (2019). Zero Defects (Crosby). Retrieved [insert date] from Toolshero: https://www.toolshero.com/quality-management/zero-defects/

Published on: 06/15/2018 | Last update: 01/31/2024

Add a link to this page on your website:

<a href=”https://www.toolshero.com/quality-management/zero-defects/”>Toolshero: Zero Defects (Crosby)</a>