Supplier Relationship Management (SRM)

Supplier Relationship Management: this article explains the Supplier Relationship Management (SRM) in a practical way. In addition to explaining what it is (and meaning), this article also discusses the relationship with E-procurement, the importance of strategic purchasing, a brief explanation of the Kraljic matrix and the Interdependence. Enjoy reading!

What is Supplier Relationship Management (SRM)?

Manufacturing companies are largely dependent on their suppliers. They need the raw materials, excipients, and semi-finished goods to make their own products. This means that they are very dependent on their suppliers; the time and reliability of the delivery and the price-quality ratio are examples of this.

Strategic purchasing usually consists of the search for the right supplier (sourcing), who supplies the right products at the best conditions. In addition, operational procurement support is part of strategic procurement.

Companies that focus on services are also dependent on their suppliers. Banks and insurance companies, for example, are focused on the software suppliers that offer them the best opportunities for the best software.

Supplier Relation Management (SRM) can play an important role in all these cases. This supplier management strives for a mix of good price, quality, cooperation level, delivery time, and delivery reliability from the supplier.

Supplier Relationship Management software

Supplier Relationship Management is about a systematic approach to assessing supplier contributions and finding out how successful they can be. By maximising the suppliers’ performance, the organisation will thrive.

This is why it is good to create a positive relationship between buyers and suppliers and, for certain activities, to involve the supplier in this process. Supplier Relationship Management (SRM) is usually a software system.

Supplier Relationship Management and E-procurement

By outsourcing activities, companies become increasingly dependent on suppliers in the areas of innovation, stock security, sustainability, and cost savings, among others.

Strategic partnership with suppliers is therefore high on the agenda, making Supplier Relationship Management (SRM) the tool to distinguish itself from competitors.

It is mostly organisations that purchase goods and products indirectly that can benefit from Supplier Relationship Management (SRM). This mainly involves looking for the right supplier, maintaining contacts with this supplier, and handling the entire ordering and payment process. In this way, it is mainly used for operational support, with e-procurement being the most popular partial functionality.

E-procurement provides maximum convenience and optimal control of the entire procurement process. This concerns the electronic handling of processes and transactions relating to purchase orders. Savings can be achieved when a company can purchase under contracted conditions, with budgetary safeguards in place, and a good relationship with the supplier.

E-procurement involves controlling the entire operational procurement process. This process, which is fully automated, consists of requesting, approving, ordering, monitoring, and registering deliveries. The main advantage of this is that no unnecessary, manual, or error-prone steps will be made.

E-procurement is particularly suitable for governments and large companies. Through accurate supplier selection and by entering purchase agreements with suppliers, the tasks of purchasing employees are then eliminated.

Strategic procurement

The aim of Supplier Relationship Management (SRM) is to streamline and improve processes between the company as buying party with its suppliers. As a result, the service to our own customers can also be visibly improved.

In this way, attention is paid to strategic procurement. Procurement is becoming more and more professional. It is no longer just about cost reduction; the focus has shifted to the value that the product or service has for the customer.

Strategic relationships with suppliers fit in perfectly with this, because businesses are increasingly dependant on strategic suppliers. Supplier Relationship Management (SRM) creates a common frame of reference to enable effective communication between companies and suppliers in order to measure the performance of suppliers.

In this way, suppliers are categorised within Supplier Relationship Management (SRM) based on their importance to the company. Business processes are also coordinated and relationships with suppliers improved. By improving strategic information with key suppliers, (even) better products and services can be developed.

Supplier Relationship Management and the Kraljic-matrix

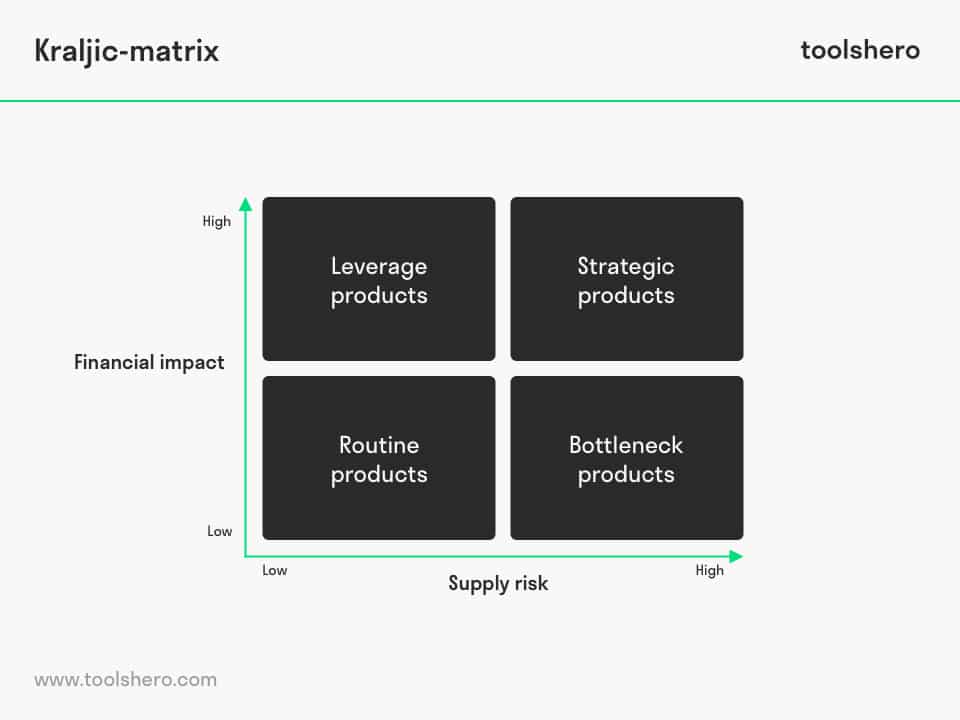

The Kraljic matrix is especially important in the field of cooperation and development of the best products. This model shows which purchasing strategy best suits the products purchased from suppliers. On the one hand, this matrix looks at the financial impact of purchased products on the company and at the supply risk on the other. This results in products that can be divided into four categories.

Figure 1 – Kraljic Matrix

Routine products

Routine products have a low supply risk and a low financial impact. From a technical point of view, procurement is the least problematic. Think of raw materials and consumables. E-procurement fits in perfectly with this.

Leverage products

For leverage products, the supply risk is low, but the financial impact is high. By making smart purchases, there is a good chance that the company will be able to make a profit. These products can easily be purchased from different suppliers, at the best price. Good framework agreements and targeted pricing offer many opportunities here.

Bottleneck products

Bottleneck products carry a high supply risk, but a low financial impact. These products are the most vulnerable part of the entire delivery. They are indispensable for the production process and are often difficult to obtain.

As a result, a supplier has power and this can have a negative impact on the relationship with the company. In many cases, companies would do well to build up buffer stocks of these products.

Strategic products

Strategic products carry a higher supply risk and a high financial impact. These are unique products that are made specifically for the company by the supplier. These are also called ‘tailor made.’

The strategy, in which the suppliers are approached as partners, fits in with this. The relationship between company and supplier is crucial. When the supplier drops out, the company cannot maintain its consistency.

For all the above possibilities, Supplier Relationship Management (SRM) focuses on developing a mutually beneficial relationship with suppliers. The supplied products promote the quality, efficiency, effectiveness, and innovation of the company.

Supplier Relationship Management and mutual dependency

As was clear from the comparison with Kraljic, supplier contribution is an important part of Supplier Relationship Management (SRM) and has an impact on the success of the organisation.

Different suppliers have different impacts on the company’s profitability. There are many different supplier relationships and levels. Supplier Relationship Management (SRM) focuses on all suppliers and gives them all equal attention. With this in mind, suppliers can be segmented and selected.

Together with suppliers, we look at the strategic importance of the organisation and whether processes are on schedule. The supplier and customer are dependent on each other and must work together as strategic partners, improve processes, discuss innovation with one another, and improve the product.

Suppliers should be aware that they contribute to the quality of the final product. Supplier relationship management can be applied at all levels of partners. With the Kraljic model in mind, it is clear that the goals vary at different levels. Major suppliers make a strategic contribution and therefore require a partnership approach.

Now it’s your turn

What do you think? Do you recognize the explanation about Supplier Relationship Management (SRM) or do you have any additions? What do you think are success factors that can contribute to positive relationships with suppliers?

Share your experience and knowledge in the comments box below.

More information

- Lambert, D. M., & Schwieterman, M. A. (2012). Supplier relationship management as a macro business process. Supply Chain Management: An International Journal, 17(3), 337-352.

- Moeller, S., Fassnacht, M., & Klose, S. (2006). A framework for supplier relationship management (SRM). Journal of Business-to-Business Marketing (Routledge), 13(4), 69-94.

- Park, J., Shin, K., Chang, T. W., & Park, J. (2010). An integrative framework for supplier relationship management. Industrial Management & Data Systems, 110(4), 495-515.

How to cite this article:

Mulder, P. (2019). Supplier Relationship Management (SRM). Retrieved [insert date] from Toolshero: https://www.toolshero.com/strategy/supplier-relationship-management-srm/

Original publication date: 07/14/2019 | Last update: 05/30/2023

Add a link to this page on your website:

<a href=”https://www.toolshero.com/strategy/supplier-relationship-management-srm/”> Toolshero: Supplier Relationship Management (SRM)</a>