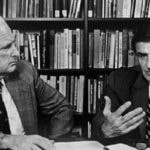

Taiichi Ohno biography and quotes

Taiichi Ohno (1912 – 1990) was a successful Japanese engineer and the founding father of the Toyota Production System (TPS). This became later the LEAN Manufacturing philosophy which is still used in today’s business and manufacturing world.

Taiichi Ohno biography

Taiichi Ohno graduated of the Nagoya Technical High School in Japan.

After his graduation, Taiichi Ohno joined the Toyoda Spinning and Weaving works in 1932. This was later sold to a British company named the Platt Brothers. After selling the business, the Toyoda family decided to invest the money in the manufacturing of motor cars (Toyota).

In 1943 Taiichi Ohno worked as a production engineer and met the challenge to boost their productivity to compete with the American automotive industry. It was vital for the Toyoda family to survive and this led to considerable pressure.

Luckily during the following years, Taiichi Ohno managed to get the situation under controle and he decided to eradicate inefficiency and eliminate waste within the company’s production process. This became the core for the Toyota Production System (TPS).

Elements like muda (the elimination of waste), jidoka (the injection of quality) and Kanban (the tags used as part of a system of Just In Time stock control) were designed, developed, tested and optimized.

He also kept asking repeatedly why the company needed to (expensively) stockpile vast quantities of components for its production line. This led to the development of the Just In Time (JIT) method of stock control.

Taiichi Ohno worked his way up from shop-floor supervisor to executive within Toyota. As he openly discussed production processes, which was frowned upon within the company, he was he was sent to consult with suppliers later in his career.

The success of TPS was helped to some extent by the fact that Toyota’s main factory in Japan is situated in Toyoda City, near Nagoya. It was easy for Toyota to choose parts on demand and ensure that they arrived at its doors as and when they were needed.

Taiichi Ohno ‘s success of TPS development (Daily Improvements, Good Thinking and Good Products) within Toyota was spread to some extent by the telling of his story in books and articles translated into English.

He was a great originator of new ideas, combined with a unique leadership style. Taiichi Ohno had the ability to identify the best of a competitor’s systems and to adapt these to the Japanese manufacturing and business environment. This was one of the key successes of the growth of Toyota as a car manufacturer and organization.

Famous quotes

- “All we are doing is looking at the time line, from the moment the customer gives us an order to the point when we collect the cash. And we are reducing the time line by reducing the non-value adding wastes.”

- “Progress cannot be generated when we are satisfied with existing situations.”

- “The Toyota style is not to create results by working hard. It is a system that says there is no limit to people’s creativity. People don’t go to Toyota to ‘work’ they go there to ‘think’.”

- “Without standards, there can be no improvement.”

- “Having no problems is the biggest problem of all.”

- “Standards should not be forced down from above but rather set by the production workers themselves.”

- “Something is wrong if workers do not look around each day, find things that are tedious or boring, and then rewrite the procedures. Even last month’s manual should be out of date.”

- “Data is of course important in manufacturing, but I place the greatest emphasis on facts.”

- “The more inventory a company has, the less likely they will have what they need.”

- “No goal, regardless of how small can be achieved without adequate training.”

- “Costs do not exist to be calculated. Costs exist to be reduced.”

- “The more inventory a company has, the less likely they will have what they need.”

- “We are doomed to failure without a daily destruction of our various preconceptions.”

Publications and books by Taiichi Ohno et al.

- 2007. Workplace Management. Translated by Jon Miller, Gemba Press.

- 1989. L’esprit Toyota.

- 1988. Just in Time for Today and Tomorrow. Productivity Press.

- 1988. Workplace Management. Productivity Press.

- 1988. Toyota Production System: Beyond Large-Scale Production. Productivity Press.

- 1987. The Toyota Production System (Doctoral dissertation, Monterey Institute of International Studies).

- 1985. Kanban: just-in-time at Toyota.

- 1983. Toyota Seisan Hoshiki no Tenkai (application of Toyota Production System). Tokyo, Japan: Nihon Noritsu Kyokai.

- 1982. How the Toyota production system was created. Japanese Economic Studies, 10(4), 83-101.

- 1982. The origin of Toyota production system and kanban system. In Proceedings of the International Conference on Productivity and Quality Improvement (pp. 3-8). Industrial Engineering and Management Press Atlanta, Ga.

- 1978. Toyota Production System–Aiming at an Off-Scale Management. Diamond Co., Tokyo.

How to cite this article:

van Vliet, V. (2017). Taiichi Ohno. Retrieved [insert date] from Toolshero: https://www.toolshero.com/toolsheroes/taiichi-ohno/

Original publication date: 06/29/2017 | Last update: 08/23/2023

Add a link to this page on your website:

<a href=”https://www.toolshero.com/toolsheroes/taiichi-ohno/”>Toolshero: Taiichi Ohno</a>