Theory of Constraints by Eliyahu Goldratt

Theory Of Constraints (TOC): this article explains the Theory Of Constraints or TOC, developed by Eliyahu Goldratt in a practical way. Next to what it is, this article also highlights the strategy plan and steps, the internal and external constraints and the importance of continuity. After reading you will understand the basics of this strategy theory and management philosophy. Enjoy reading!

What is the Theory Of Constraints (TOC)?

Eliyahu Goldratt assumed that the ultimate goal of most organizations is to make a profit and other goals are derived from this goal.

Goldratt indicated that it is especially the constraints that prevent organizations from generating maximum profits.

Every organization has at least one constraint. In order to deal with constraints, Eliyahu Goldratt developed the management philosophy of the Theory Of Constraints (TOC).

On the one hand theory of constraints, also known as the thinking processes, focuses on how quickly results can be achieved. This output is called “throughput”.

On the other hand, theory of constraints focuses on the factors that hinder the speed of this “throughput” (bottleneck). The “throughput” will be increased when the “bottleneck” can be reinforced or eliminated:

Throughput (T)

This is the rate at which an organization generates money through sales. The output is measured for on the basis of for example money, the number of products or services.

Inventory (I)

Inventory consists of the investments in assets of an organization, that can be (quickly) converted into liquid assets.

Operation Expenses (OE)

This is the money that has been invested to turn inventory into throughput such as labour costs, material costs and depreciations.

Theory of Constraints (TOC) & its Applications – Crash Course

Theory Of Constraints strategy plan

The management philosophy theory of constraints can be practically executed.

The rate of the “throughput” is hindered by the “bottleneck”. To identify, reinforce or eliminate this “bottleneck” it is important to follow the five steps below:

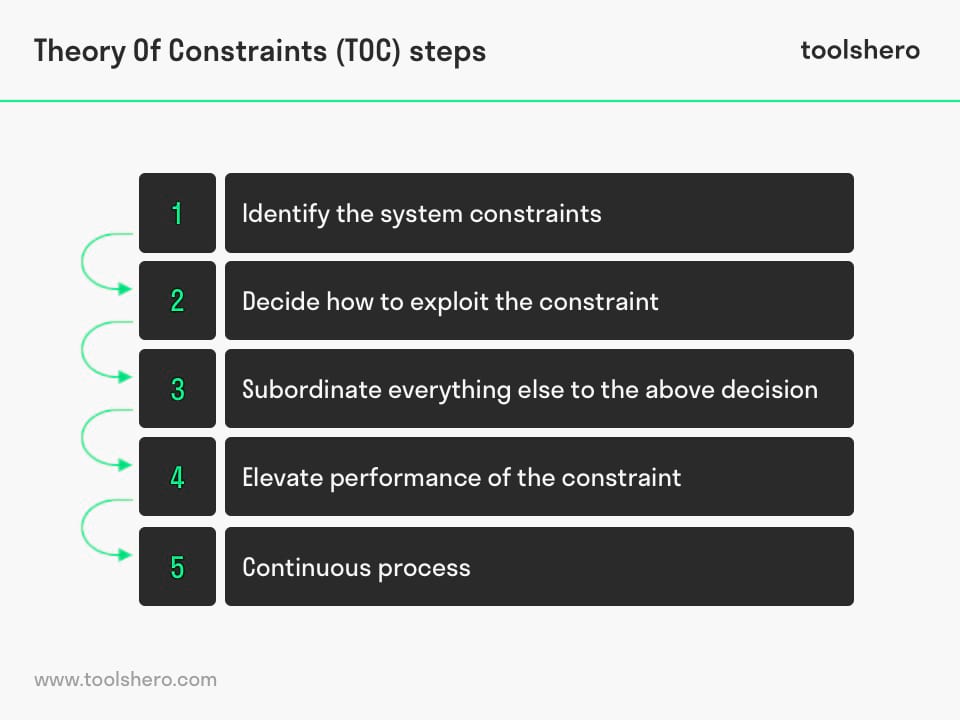

Figure 1 – Steps of the Theory of Constraints

Step 1 of the Theory of Constraints: identify the system constraints

The weakest link in an organization is identified whereupon it must be decided whether its causes are physical or policy-related.

Step 2: decide how to exploit the constraint

The organization as a whole determines how this constraint can be eliminated as a result of which the “throughput” can actually be increased.

Should these actions not lead to an increase, it is considered advisable to abandon the breakthrough of this constraint.

Step 3: subordinate everything else to the above decision

The organization as a whole must side with the adopted solution, as a result of which the “constraint” is solved. It is wise to make an assessment in between steps 3 and 4, to establish whether performance is still being hindered by this earlier constraint.

Step 4: elevate performance of the constraint

Other adjustments can be used to break through the “constraints”.

This could involve changes in the existing system reorganization, increase of sales or changes in the market. Such adjustments require investments and will only be deployed after all other options have been considered.

Step 5 of the Theory of Constraints: continuous process

After the implementation of the opted solution and after elimination or breakthrough of the constraint, the process starts over again from step 1. On the one hand the impact of the implemented solution is looked at and on the other hand new constraints are identified and broken through.

Internal and external constraints

Constraints can be an internal and an external part of an organization. Internal constraints present themselves when there is too little output to meet the demands in the market. By identifying and reinforcing this constraint, a breakthrough is thus realized.

Examples of such constraints are badly deployed production methods, lack of competent employees and bad policies as a result of which a system cannot function optimally.

External constraints indicate a too large output with respect to the demand in the market. In that case an organization should cultivate the market which leads to a higher demand. However, this often requires capital.

Theory of Constraints and continuity

Eliyahu Goldratt was in favour of looking at one constraint per cycle.

By focusing all attention on one constraint, this could be dealt with more adequately. The other links in the system are regarded as non-constraints and are therefore not reinforced or broken through.

Reinforcement or breakthrough of the identified constraint will automatically lead to another constraint that will have to be identified again.

The whole process starts over again. Therefore the Theory Of Constraints encourages an organization to improve its system continuously.

Now It’s Your Turn

What do you think? Is the Theory of Constraints (TOC) applicable in today’s modern organizations and companies? Do you recognize the practical explanation or do you have more additions? What are your success factors for the good continuous improvement strategy?

Share your experience and knowledge in the comments box below.

More information

- Goldratt, E. M. and Cox, J. (2005). A Process of Ongoing Improvement. Journal of Manufacturing Technology Management 16.3 (2005): 302.

- Goldratt, E. M. (1990). Theory of constraints. North River Press.

- Goldratt, E. M. (2009). Standing on the shoulders of giants: production concepts versus production applications. The Hitachi Tool Engineering example. Gestão & produção, 16(3), 333-343.

How to cite this article:

Mulder, P. (2011). Theory of Constraints (Goldratt). Retrieved [insert date] from Toolshero: https://www.toolshero.com/strategy/theory-of-constraints-goldratt/

Original publication date: 06/08/2014 | Last update: 12/27/2023

Add a link to this page on your website:

<a href=”https://www.toolshero.com/strategy/theory-of-constraints-goldratt/”>Toolshero: Theory of Constraints (Goldratt)</a>