SIPOC Model explained

SIPOC model: this article describes the concept of the SIPOC model in a practical way. Next to what it is adn the theory is explained, this artcile also highlights the importance of the transformation process, an example and a SIPOC Model template to get started yourself. After reading you will understand the basics of this quality management tool. Enjoy reading!

What is SIPOC model? Theory explained

SIPOC is a method to properly describe the transformation process within a company that offers products and / or services.

It’s a tool for process improvement that summarises the input and output of one or multiple processes in tables. The practice of applying this model is also referred to as process mapping. The end product is a so called high level process map.

Acronym

SIPOC stands for Supplier, Inputs, Process, Output and Customers, also the names of the columns in the model,.

Origin

The tool was created in the ’80s. It is a programme within quality systems, such as Six Sigma, Kaizen and Lean manufacturing. The method is relatively easy to use using flip charts, post its or a template.

The SIPOC Model is about the transformation process

The SIPOC model method ultimately creates a process in which all factors influencing the transformation process and which parties are involved. By mapping this, a company can find out everything that needs to be worked out to have their business processes run smoothly.

The supplier supplies input in the form of raw and other materials, semi finished products, knowledge and expertise. Everything is tailored to a company’s needs. This is an important step in the process towards the eventual shape of the final product or service. This output has to comply with and perhaps even surpass the customer’s requirements.

The customer is not necessarily an external party, they can also be from within the organisation. This means supplier / customer relations can also exist within a company.

The SIPOC model helps prevent that parts of the transformation process are overlooked. The method further clarifies the process to employees who have little or no knowledge about the transformation to the final product. It also helps employees define a new process clearly.

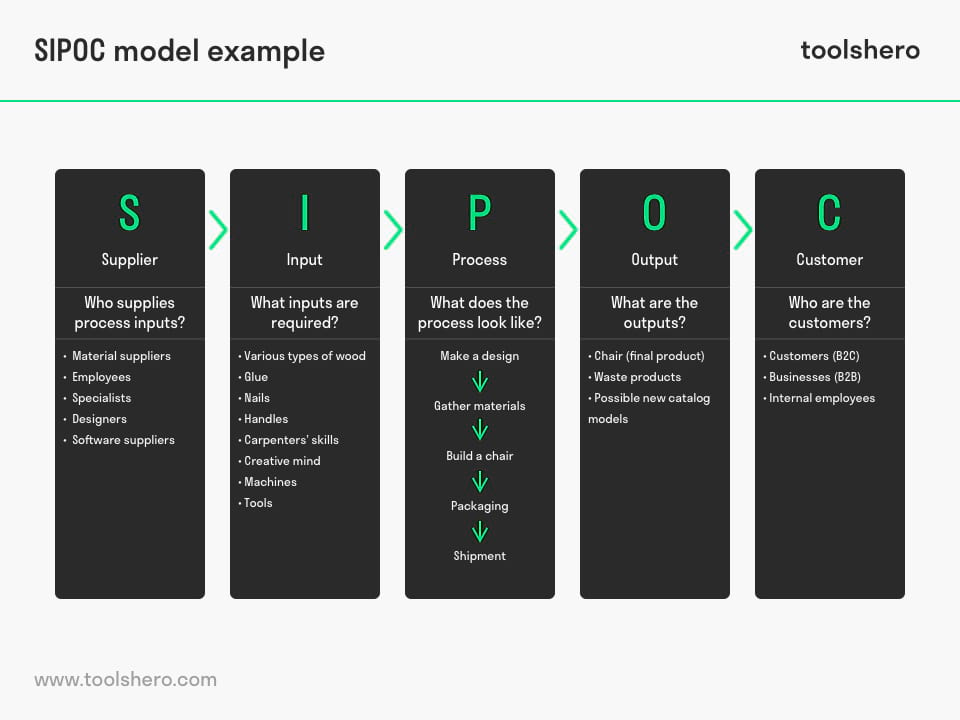

SIPOC Model example

The SIPOC model method describes who supplies which products to the production process. What exactly is being delivered by various players? What is the final result? Who is the end product intended for?

These questions will become clear. Below, various aspects of the model are explained with a practical example.

Figure 1 – a practical SIPOC Model example

Supplier

This is the party that supplies products or services to the process. The aim of this aspect is to identify the suppliers. These can be both internal or external parties. What’s necessary for the process and what’s being used? We can find a description for this in Input.

The supplier supplies, for example, materials and information. Whatever needs to be gathered before the process can start, is supplied by these parties. They can be suppliers of raw materials or knowledge, skills and information.

Lets consider the example of a furniture manufacturer. Its suppliers supply the wood, nails and glue. On top of that they also supply the facility with skilled employees. The suppliers also takes care of a designer of tables and chairs and a supplier of design software.

Input

In addition part within SIPOC model to the suppliers themselves, it’s now also known what they supply. The input required for the process is about materials, service and information.

The furniture manufacturer needs raw materials like various types of wood. An example of other materials are glue and nails. An example of a semi finished product is metal handles for closets. The carpenters’ skills are also necessary, as is the creative mind of the designer. The right input into the system by the software specialist are also required. Machines and tools are also needed.

Process

The process itself is described in a document, manual or work instruction. By clearly describing all the steps, standard work can be delivered in the output, without a lot of deviations.

On top of that, everybody involved in the process is familiar with their own actions. This means it’s easier to talk to each other when something doesn’t go right and correct each other. All furniture in a given series that leaves the furniture manufacturer, will have be very uniform and similar in quality.

Output

The outputs of the process can be seen as the end product. In addition to the end product, waste products are also an example of the Output.

The furniture manufacturer, besides furniture, also creates:

- Jobs

- Designs

- Website with new furniture models

- Wood chips that leave the factory as rubbish

Customer

The person or company you supply to, is the so-called end user. This could be the actual customer who buys furniture from the manufacturer. But it can also be employees who work at the factory.

Customer requirements are important throughout the process. When the output doesn’t comply with the customer requirements, the quality can’t be guaranteed.

Stakeholders

The above means that only direct suppliers and customers are included in this process

Other stakeholders, such as banks, funding bodies or licensing companies, aren’t included in this process. It’s also not customary for quality features and / or specifications to be mentioned.

The SIPOC Model and involvement

It’s important to create a SIPOC model diagram with a group of employees. Every team member involved must have a chance to contribute to the process.

Besides their own views, they can also decide their role within the process. It creates mutual understanding and a shared idea of the process, which leads to more involvement.

Ultimately, it helps to achieve operational excellence within an organisation. A SIPOC model gives everybody clear insight into the reasons the process was started. This prevents confusion in later a later stage of the process. It also clarifies beforehand who is involved in the process and what is needed from everyone.

SIPOC Model template

Start describing the transformation/production process, its influencing factors and involved parties with this ready to use SIPOC model template.

Download the SIPOC model template

This template is exclusively for our paying Toolshero members. Click here to see if a membership is something for you!It’s Your Turn

What do you think? What is your experience with the SIPOC model? How do you describe the production process? Do you recognize the practical explanation or do you have more additions? What are your success factors for good quality management?

Share your experience and knowledge in the comments box below.

More information

- Antony, J., Singh Bhuller, A., Kumar, M., Mendibil, K., & Montgomery, D. C. (2012). Application of Six Sigma DMAIC methodology in a transactional environment. International Journal of Quality & Reliability Management, 29(1), 31-53.

- Reddy, G. P., & Reddy, V. V. (2010). Process improvement using Six Sigma–a case study in small scale industry. International Journal of Six Sigma and Competitive Advantage, 6(1-2), 1-11.

- Shankar, R. (2009). Process improvement using six sigma: a DMAIC guide. ASQ Quality Press.

How to cite this article:

Mulder, P. (2018). SIPOC Model. Retrieved [insert date] from Toolshero: https://www.toolshero.com/quality-management/sipoc-model/

Original publication date: 03/02/2018 | Last update: 08/22/2023

Add a link to this page on your website:<a href=”https://www.toolshero.com/quality-management/sipoc-model/”>Toolshero: SIPOC Model</a>