8D Report and template

8D Report: this article explains the 8D Report in a practical way. Besides the explanation of what this concept is, we also the 8 disciplines and the importance of teamwork. Next to that we also provide a template to get strated. Enjoy reading!

What is an 8D Report? The meaning

The 8D Report or 8d corrective action report is a problem-solving approach for product and process improvement. Furthermore, 8D Methodology is used to implement structural long-term solutions to prevent recurring problems. The 8D Report was first used in the automotive industry.

During World War II the 8D Method was used in Team Oriented Problem Solving (TOPS) in the United States under Military Standard 1520. It was later used and popularized by car manufacturer Ford.

In the 1990s Ford continued to develop the 8D process as a result of which the process is said to have found its origin in the automotive industry. Today, the 8D Method can be used to write formal reports and it can be applied as a working and thinking method for smaller problems.

The 8D Report is also used as a means of communication within companies, which makes the problem solving method transparent and can therefore be applied to the entire production chain. The 8D method is also known as: Global 8D, Ford 8D or TOPS 8D.

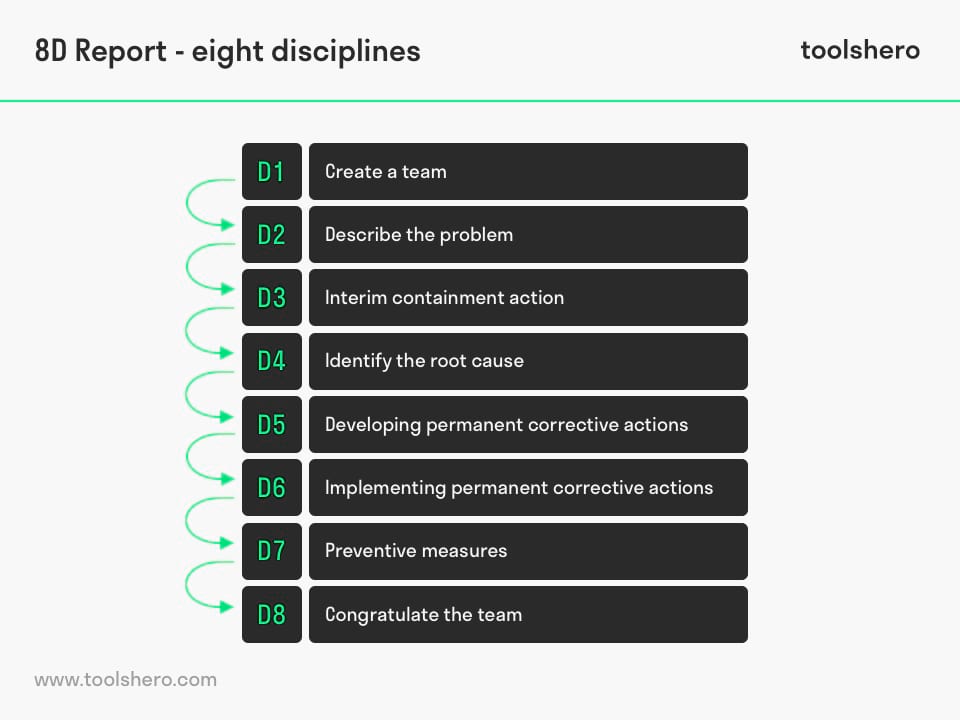

8D Report: eight disciplines

The 8D Methodology mainly focuses on solving problems and comprises 8 steps or disciplines. It helps quality control staff find the root cause of problems within a production process in a structured manner so that they can resolve the problem(s).

In addition, it helps implement product or process improvements, which can prevent problems. The 8D Report is about mobilizing a good team that has sufficient expertise and experience to solve or prevent problems. The 8D Report consists of 8 disciplines that describe corrective measures based on the statistical analysis of the problem. This results in the following eight process steps:

Figure 1 – 8D report: the eight disciplines

D1 – Create a team

Mobilizing a good team is essential. The team must preferably be multidisciplinary. Due to a varied combination of knowledge, skills and experience, one can look at a problem from different perspectives.

Besides having an effective team leader, it is also advisable to record team structure, goals, different team roles, procedures and rules in advance so that the team can begin taking action quickly and effectively, and there is no room for misunderstandings.

D2 – Describe the problem

Define the problem as objectively as possible. The 5W2H analysis (who, what, when, where, why, how, how much) is a welcome addition to the problem analysis and can help to arrive at a clear description of the problem.

D3 – Interim containment action

It may be necessary to implement temporary fixes. For example, to help or meet a customer quickly or when a deadline has to be met. It is about preventing a problem from getting worse until a permanent solution is implemented.

D4 – Identify the root cause

Before a permanent solution is found, it is important to identify all possible root causes that could explain why the problem occurred. Various methods can be used for this purpose, such as the fishbone diagram (Ishikawa) which considers factors such as people, equipment, machines and methods or the 5 whys method.

All causes must be checked and/ or proven and it is good to check why the problem was not noticed at the time it occurred.

Take a look at our article on Root Cause Analysis, a method of problem solving that aims at identifying the root causes of problems or incidents.

D5 – Developing permanent corrective actions

As soon as the root cause of the problem has been identified, it is possible to search for the best possible solution. Again various problem solving methods can be used such as value analysis and creative problem solving.

From here, permanent corrective actions can be selected and it must be confirmed that the selected corrective actions will not cause undesirable side effects. It is therefore advisable to define contingency actions that will be useful in unforeseen circumstances.

D6 – Implementing permanent corrective actions

As soon as the permanent corrective actions are identified, they can be implemented. By planning ongoing controls, possible underlying root causes are detected far in advance.

The long term effects should be monitored and unforeseen circumstances should be taken into account.

D7 – Preventive measures

Prevention is the best cure. This is why additional measures need to be taken to prevent similar problems. Preventative measures ensure that the possibility of recurrence is minimised. It is advisable to review management systems, operating systems and procedures, so that they can be improved procedures if necessary.

D8 – Congratulate the team

By congratulating the team on the results realized, all member are rewarded for their joint efforts. This is the most important step within the 8D method; without the team the root cause of the problem would not have been found and fixed.

By putting the team on a pedestal and sharing the knowledge throughout the organization, team motivation will be high to solve a problem the next time it presents itself.

The 8D Report is also about teamwork

A strength of this method is its focus on teamwork. The team as a whole is believed to be better and smarter than the sum of the qualities of the individuals. Not every problem justifies or requires the 8D Report.

Furthermore, the 8D Report is a fact-based problem solving process, which requires a number of specialized skills, as well as a culture of continuous improvement. It could be that training of the team members is required before 8D can work effectively within an organization.

The team must recognize the importance of cooperation in order to arrive at the best possible solution for implementation.

8D Report template

Ready to start with the 8D problem-solving approach? Start describing the different disciplines of 8D with this 8D Report template.

Download the 8D Report template

This template is exclusively for our paying Toolshero members. Click here to see if a membership is something for you!It’s Your Turn

What do you think? Can you apply the 8D Report in today’s modern business companies? Do you recognize the practical explanation or do you have more suggestions? What are your success factors for problem analysis and problem solving?

Share your experience and knowledge in the comments box below.

More information

- Behrens, B. A., Wilde, I., & Hoffmann, M. (2007). Complaint management using the extended 8D-method along the automotive supply chain. Production Engineering, 1(1), 91-95.

- Krajnc, M. (2012). With 8D method to excellent quality. RUO. Revija za Univerzalno Odlicnost, 1(3), 118.

- Possley, M. (2016). 8D Team Based Problem Solving – 2nd Edition: An Instructive Example. CreateSpace Independent Publishing Platform

How to cite this article:

Kuijk, A. (2017). 8D Report and template. Retrieved [insert date] from toolshero: https://www.toolshero.com/problem-solving/8d-report/

Original publication date: 11/03/2017 | Last update: 11/02/2023

Add a link to this page on your website:

<a href=”https://www.toolshero.com/problem-solving/8d-report/”>Toolshero: 8D Report and template</a>

3 responses to “8D Report and template”

Nice information it is very useful

What stands for D in 8D…?

Hi Sachin,

The D in 8D stands for 8 Disciplines / Eight Disciplines.

Kind regards,

Tom