House of Quality (HOQ) explained

House of Quality (HOQ): this article provides a practical explanation of the concept of House of Quality (HOQ), developed by Yoji Akao and Shigeru Mizuno. This article contains a general definition of this concept, its elements, processes. You will also find a downloadable House of Quality template in this article to get started. After reading, you will have a basic understanding of this quality management tool. Enjoy reading!

What is House of Quality (HOQ)?

The quality of products and / or services isn’t just important for businesses themselves, but especially for their customers. Customers decide what they think of a product / service.

The better the quality in the opinion of the customers, the more likely that customers will have a positive response, come back, and recommend the product or service to others.

Still, it’s not easy to meet the quality standards that customers demand. The Quality Function Deployment (QFD) or the House of Quality (HOQ) makes that possible. QFD is part of the Lean Six Sigma quality system.

It’s a method to inventory customer wishes and market demands and to then include these in the design brief. This method enables organisation to focus even more on what their customers want. The result of the QFD method is a data matrix, also called House of Quality (HOQ). This house of quality can take on different shapes. In all cases, however, the representation will resemble a house.

The QFD method was invented in 1960 by Japanese planning expert Yoji Akao and Japanese quality expert Shigeru Mizuno.

Initially, QFD was used at Japanese shipyards, having resulted from William Deming‘s PDCA cycle, which stands for Plan, Do, Check, and Act.

House of Quality (HOQ): The phases of the QFD process

The entire process for qfd house of quality is complicated, but is explained in a practical way in this article. You can also download the Toolshero House of Quality template to practice performing the different steps of this method.

Phase 1: product definition

This first phase is mainly about collecting user input. This is important to safeguard as many interests as possible in the product development process.

Understand the customers: find out what they need in their daily activities.

Activities that help make this possible are, for example: interviews, focus groups and other related methods such as questionnaires, user stories, etc. How the customer requirements translate into design requirements is determined in the following phases.

Phase 2: product development

During this second phase, the teams work on the product specifications that have been included and prioritized in the House of Quality. They translate these specifications into component characteristics, assembly characteristics and the definition of functional requirements.

Phase 3: process development

During the process development phase, the company will design the final production and assembly processes. This is necessary to comply with all product specifications.

Different methods can be used during this phase, such as Business Process Mapping (BPM) and Business Process Re-engineering (BPR).

Phase 4: Process Quality Control

During this last phase, the company mainly focuses on optimizing the quality of the process. The employees who use the QFD process provide the input for this.

Through daily use they are able to provide very specific information about critical characteristics, checks, inspections and tests. This is to ensure that all quality requirements are met.

House of Quality (HOQ) and quality functions

The quality house is part of QFD and represents quality control.

There’s also a focus on the execution of a quality plan and applying the resources to implement such a plan. Because quality functions are being established, it’s considered part of Lean Six Sigma.

The quality house makes it easy to translate customer wishes and market demands into a design. In addition to function requirements, the functional specifications and technical design will also be considered. For instance, through the use of programme and system tests, it can be evaluated if the product meets the customers’ expectations.

House of Quality (HOQ) is team-oriented

The House of Quality (HOQ) is aimed at product development that has been inspired by customer wishes. In order to actually meet those wishes, it’s important to first carefully listen to the customers.

All their ideas and wishes are translated into a realistic and feasible plan, looking at what is and isn’t possible based on priorities.

This is a team process; all team members contribute and the process steps are taken several times. All the team members will have to listen to each other and ensure that quality is taken to a higher level and safeguarded. This entire process of converting customer wishes to design requirements generally follows the steps below:

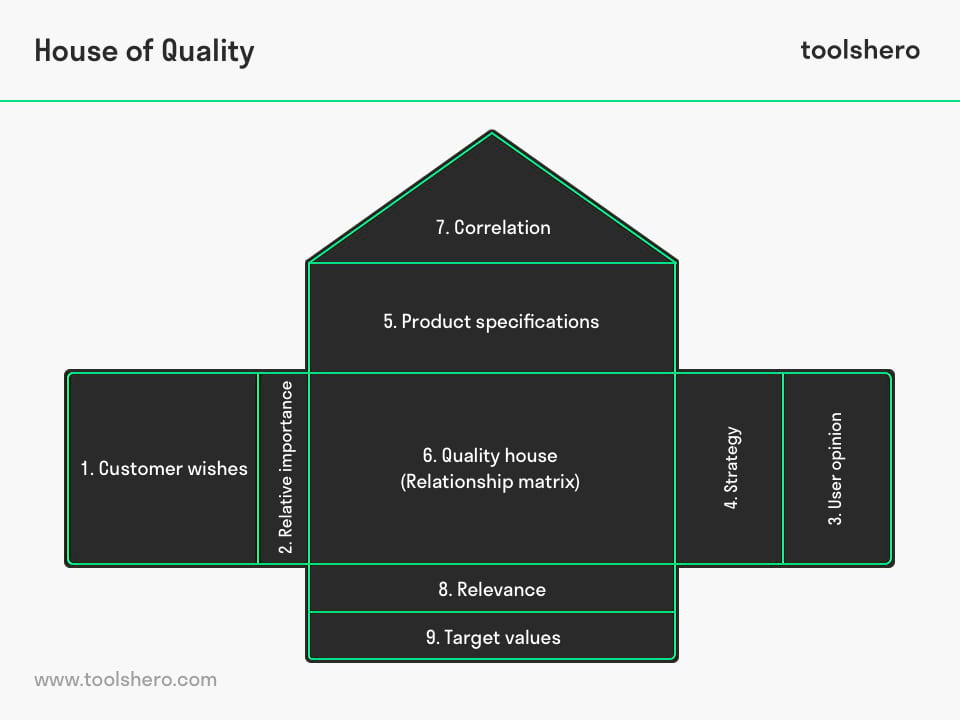

Figure 1 – The 9 Elements of The House of Quality

1. Identify customer wishes

The first step is to find out what customers really want. That requires extensive research. Think of customer interviews, questionnaires, and collecting reviews. Complaints can also be a valuable source of information regarding what customers want exactly.

Both existing customers and future customers can be useful sources of information. The goal of this phase is to get a better understanding of the customers’ wishes and to enable them to suggest their own ideal solution.

Key customer needs are included on the left side of the Toolshero House of Quality template. In the example included in the template, customers indicate that they place great value on the following features when purchasing a new phone:

- Size

- Weight

- Ease to use

- Reliability

- Costs

- Screen size

- Battery life

- High quality camera

Directly on the right-hand side of this list, the percentage of customer interest is calculated. To do this, proceed to the next step: relative importance.

2. Relative importance

During this phase, you look at which customer wishes or requirements are considered the most important (importance rating). This is indicated with ‘relative importance’. It involves assigning a score between 1 and 10, with 1 being least important, and 10 being most important.

Interviews can be used to filter customer priorities. The value that a customer assigns to a certain specification or solution can also differ from what the manufacturer had in mind.

For instance, a professional photographer might think that the quality of the lens and shutter time are more important than battery life.

3. User opinion

In addition to the above-mentioned research, the overall opinion of the user (or voice of the customer) is also important. It can be obtained from competition research.

By finding out what type of similar products competitors offer and what customers think of those, you can form a general impression and the importance to the customer.

If the competitor offers certain extras or a slightly different modified product that users like, the manufacturer can do the same. With this information, they can adapt their own products and / or services. This to satisfy customers.

4. Strategy

Based on information that was obtained earlier, an organisation can determine a business strategy. SMART Goals, projected effort, and required resources will become clear, and a priority level can then be assigned to every adjustment, change, or addition.

It’s important that different departments work towards the same goal; disagreements or misunderstandings between departments can undermine the expected results. The priorities have to be supported by all departments.

5. Product specifications

All available data will now have to be converted into specifications and / or design details / product characteristics. This means that the customer wishes have to be translated into technical specifications. The foundation of the quality house is being built.

Horizontally above the relationship matrix, add the design requirements for a product. Examples are weight, hardware requirements, production costs or operating systems.

6. Quality house

Now the relationship between wishes and specifications is plotted in a matrix (the quality house). It becomes clear to what extent these specifications will contribute to achieving the customer wishes.

By recording specific requirements for how the product is realised, it becomes clear how to best meet customer demands.

This is also where people can question why a certain method is chosen. Because all the requirements are written down, it should be easy to later determine whether an adjustment was successful.

This is the step in the process where it ultimately revolves around. In the relationship matrix, you identify how strongly each of the parameters influences the customer’s need. Use the 3 different symbols from which you can choose.

7. Correlation

In the quality house, specifications will now be compared and evaluated.

The idea is to examine which aspects conflict and which strengthen each other, discovering the link between specifications. Eventually, this will lead to a logically feasible and traceable structure, which combines all (new) ideas.

Above the design requirements, the user indicates whether it is better to place the function lower or higher. This is indicated by an up arrow or a down arrow. In the example of the Toolshero House of Quality template, you see that the weight has a down arrow. So, a lower weight would be better.

Based on these arrows, the correlation between the different design requirements is determined. Use 1 of the following 3 options:

- + = positive correlation

- – = negative correlation

- X = no correlation

8. Relevance

Now it’s time to look at the relevance related to the specifications and/or design requirements. This is where the question is asked to what extent its feasible to make the adjustments.

In this step also fill out the right part of the House of Quality. This section discusses competitors’ scores on each of the customer needs.

Use a number between 1 and 5. These scores have no influence on the relationship ratios of the template, but serve as methods for gaining additional insight in order to serve the end user as well as possible.

9. Target values

The final step is to translate all the obtained results into design requirements and target values that will help to further improve the quality of the product and/or service.

Resources

Within the quality house, the focus during the design process is on customer wishes and/or customer requirements. However, developing and adapting physical products does require resources.

Examples are employees, computers, machines, adjustment of machines, raw materials, and so on. It’s therefore important that all those means are facilitated by the organisation.

By identifying which resources are available beforehand, it’s possible to respond more quickly to the additional resources that will be needed for the entire quality process.

House of Quality template

Now that you have read the theory about House of Quality, you can apply your knowledge in practice. Get started with this handy House of Quality excel template and make the difference!

Download the House of Quality excel template

This template is exclusively for our paying Toolshero members. Click here to see if a membership is something for you!Now it’s your turn

What do you think? Do you recognize the explanation of the House of Quality concept? What are your practical experiences with this methodology and do you see it as a valuable tool? Do you have any tips or additional comments?

Share your experience and knowledge in the comments box below.

More information

- Adiano, C., & Roth, A. V. (1994). Beyond the house of quality: dynamic QFD. Benchmarking for Quality Management & Technology, 1(1), 25-37.

- Akao, Y., & Mazur, G. H. (2003). The leading edge in QFD: past, present and future. International Journal of Quality & Reliability Management, 20(1), 20-35.

- Madu, C. N. (2006). House of Quality (QFD) in a Minute. Chi Publishers Inc.

How to cite this article:

Mulder, P. (2019). House of Quality (HOQ). Retrieved [insert date] from Toolshero: https://www.toolshero.com/quality-management/house-of-quality/

Original publication date: 06/24/2019 | Last update: 12/17/2023

Add a link to this page on your website:

<a href=”https://www.toolshero.com/quality-management/house-of-quality/”>Toolshero: House of Quality (HOQ)</a>