5S System

5S System: this article explains the 5S System, developed by Sakichi Toyoda, in a practical way. After reading you will understand the basics of this powerful quality management tool.

History 5S System

The history of 5S System seems to go back as far as the 16th Century and Venice shipbuilders. In an effort to streamline the assembly process, workers used quality process production to build ships in hours instead of days or weeks.

In the 1970s it was Sakichi Toyoda who developed the 5S System within the broader Total Production System (TPS). Over the years, the 5S System has spread and can be found within Total Productive Maintenance (TPM), the visual workplace, the Just-In-Time (JIT) process, and LEAN Manufacturing. Basically all with the same aim: improving processes with continual improvement of production and reducing waste. Or better: eliminating waste completely.

Since its inception, many types of 5S trainings have been developed. Shadow boards are used for tool management and control, enabling owners with easy tool retrieval and usage.

The 5S System is not complex and straightforward to implement. However, every execution needs a proper plan. At the end of this article some tips & tricks.

What is 5S?

There are five 5S System phases, or 5S principles. Translated from Japanese, the 5S activities are: Sort, Straighten, Shine, Standardize and Sustain.

- Seiri = sort. Sort out needed and not needed items (remove not needed)

- Seiton = straighten. Structurize; assign place and amount to needed items

- Seiso = shine. Clean to inspect and maintain

- Seiketsu = standardize. Set standards, agreements and visualize

- Shitsuke = sustain. Secure for the future

1. Seiri

Select a 5S System area to start with and assign a team. Stick ‘needed’ and ‘not needed stickers on the different materials (machines, tools, parts, boxes, chairs etc). Gather the ‘not needed’ materials in a quarantined area. As a team decide if indeed it ‘not needed’ or needed but too many of it. Remove unnecessary items and dispose of them properly. Remove all parts not in use (back to general store). Segregate unwanted material from the workplace and dispose of them properly

2. Seiton

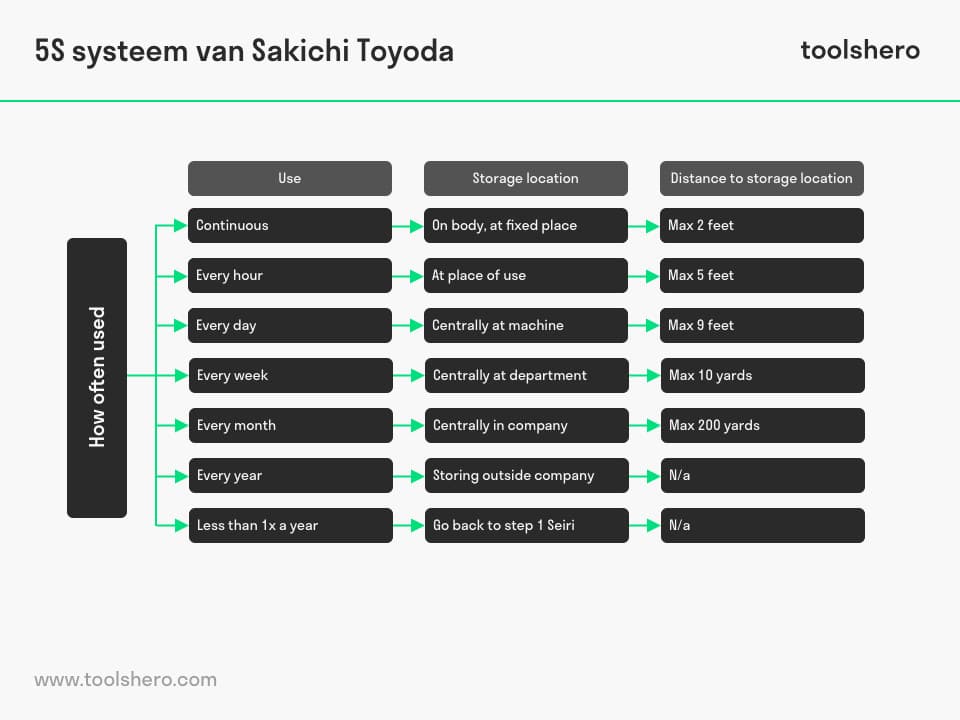

Set a place and amount for all items labelled as ‘needed’. You can use this table:

3. Seiso

A clean work environment motivates, is safer and makes efficiency increase cleaning and maintaining is more than dusting and hovering. It’s not only the outside of the machine! Embed the cleaning routines in the standard daily work of the employee. Select an area (sub area) and assign people to area/sub-area.

Set a cleaning scheme expressing clearly: what to clean, the desired result (norm, use pictures!), method (sponge, scraper, detergent), interval, time needed and who. Make sure to have participation of all levels and disciplines (incl. managers, team leads and engineers), even office personnel to create more leverage.

Emphasise that the cleaning is clean to inspect. Look for sources of contamination. This way we identify the room for improvement which could ultimately lead to less cleaning.

4. Seiketsu

Standardize the best practices in the work area. Standards are needed so all work in the same fashion. Make your standards visible. By standardizing work, tasks and stadnards are better controllable and easier to maintain. Maintain high standards of housekeeping and workplace organization at all times.

5. Shitsuke

Stimulate all to maintain the high standards. Role modelling is the key aspect here. Managers, team leads, supervisors will make the difference in this phase! Set up training for new employees. Perform regular audits and hand over improvement feedback to the team of the audited area.

Over time standards will change. Could be due to new machines, new procedures, safety rules or simply due to the fact that the overall area improved. Adjust the 5S standards together with all involved.

Remember that the 5S responsibility and competence over time has sunk in to the lowest level of your organisation. If they walk the talk together with the higher ranks you have built a solid foundation for future success.

Tips & Tricks

The 5S Initiative is not a Stand Alone Effort. The 5S Methodology practices should be part of the performance improvement plan and operational excellence strategies. Don’t form a 5S specific team. 5s needs to become the standard for all.

Management should OWN 5S

Instant killer is management not walking the talk. The 5S System message spread by a manager whose workplace does not live up to the 5S System standard loses credibility instantly. Choose your pilot project wisely. Choose a manageable space. Involve manager, supervisor and shop-floor personnel (don’t forget the forklift driver).

Visualise

The power of visual management is evident. Assure to have taken pictures prior to the start of a 5S System. Do make picture afterwards (from – to pictures). And above all MAKE IT FUN! Managers sometimes tend to forget that people perform best when fuelled within a fun, not hostile environment. Changes which are fun are mostly easier adopted into the daily routine.

It’s Your Turn

What do you think? Can you apply the 5S steps system in today’s business companies? And if so, how do you use it and what are your general results and learning lessons? Are the basics the same or are there additional success factors?

Share your experience and knowledge in the comments box below.

More information

- Gapp, R., Fisher, R., & Kobayashi, K. (2008). Implementing 5S within a Japanese context: an integrated management system. Management Decision, 46(4), 565-579.

- Liker, J., & Convis, G. L. (2011). The Toyota way to lean leadership: Achieving and sustaining excellence through leadership development. McGraw Hill Professional.

- Lorriman, A. (2017). 5S In The Workplace. Retrieved from: https://www.isolocity.com/5s-in-the-workplace/.

- Ortiz, C. A. (2015). The 5S Playbook: A Step-by-Step Guideline for the Lean Practitioner (The LEAN Playbook Series). Productivity Press; Spi edition.

- Ziegler, D. (2017). Systems2win Excel templates for implementing a Lean 5S Program. https://www.systems2win.com/solutions/5S.htm

How to cite this article:

De Weerd, P. (2016). 5S System. Retrieved [insert date] from Toolshero: https://www.toolshero.com/quality-management/5s-system/

Published on: 14/03/2018 | Last update: 06/08/2022

Add a link to this page on your website:

<a href=”https://www.toolshero.com/quality-management/5s-system/”>Toolshero: 5S System</a>