Business Process Improvement (BPI)

Business Process Improvement: this article provides a practical explanation of Business Process Improvement (BPI). Highlights include: what the methodology of BPI is, BPI tools and examples, the BPI general cycle explained and a summary. After reading, you’ll have a basic understanding of this quality management tool. Enjoy reading!

What is Business Process Improvement (BPI)? The methodology

Business Process Improvement (BPI) is a management practice and methodology that provides leaders with different methods to analyse procedures and processes, identify problems, and – if necessary – improve effectiveness, efficiency, or accuracy.

Business Process Improvement (BPI) also includes the accurate mapping of employee activities and skills. This allows things to be improved, such as smoother procedures, a more efficient workflow, and eventually business growth in general.

Activities and processes within organisations can be visualised using Business Process Mapping (BPM).

Employee competencies are recorded using competency management. Business Process Improvement (BPI) is less radical than Business Process Reengineering (BPR), which involves redesigning the process entirely.

Many organisations use BPI to discover ways to reduce the amount of time needed to carry out processes. In addition to saving time, it’s important to combat waste and friction (inefficiencies), and improve the quality of the products or services.

At a smaller scale, business leaders sometimes use BPI to ensure better rule compliance or increased customer satisfaction. BPI also helps organisations to more easily meet customer expectations, both in B2B and B2C.

If used effectively, BPI can help to improve the quality of business processes, lead to better service, lower costs, and a boost in productivity and/or efficiency.

Business Process Improvement (BPI) tools and examples

The management or executives who are responsible for business process improvement generally approach this using different methods, techniques, or philosophies. They have been developed over time to help manage and improve processes and to support structuring the activities involved in BPI.

Examples of methods that are used for BPI activities include Six Sigma (DMAIC method), Lean Management, Total Quality Management (TQM), Agile Management, and Kaizen (5S model).

Other methods or tools used to support Business Process Improvement (BPI) include:

- SIPOC analysis

- Value stream mapping (VSM)

- Mind mapping

- Business Process Mapping (BPM)

- Cause & Effect Analysis

The primary goal of these methods is to support BPI activities and help businesses to overcome challenges, remove obstacles, and avoid that planned improvements are not in line with the business objectives.

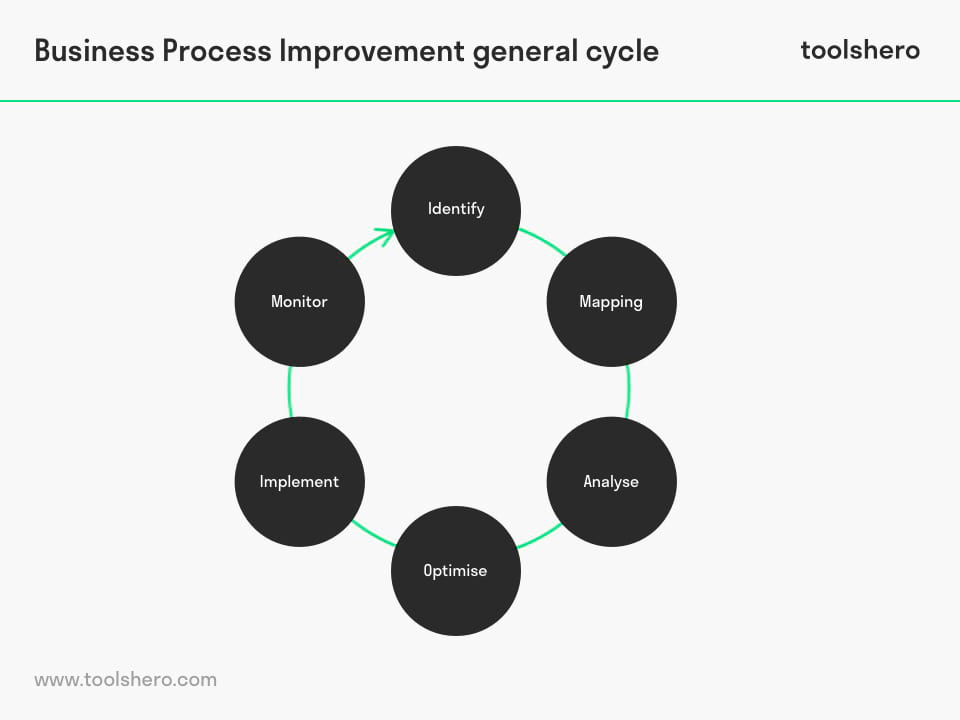

Business Process Improvement (BPI) general cycle

As described above, there are many different ways to improve business processes. However, they tend to come down to the same basic idea: analysing old processes and identifying ways to improve them.

The following steps are typical for Business Process Improvement (BPI):

Figure 1 – Business Process Improvement (BPI): General Cycle

1. Identify

Business Process Improvement is done for various reasons. Some of those are: striving for continuous improvement, cost reduction, optimisation, and poor performance. Whatever the reason, a process must be selected before optimisation can start.

2. Mapping

Once the process has been selected, it has to be written down or mapped out in its entirety. Business Process Mapping (BPM) is about visually representing a process. Identify relevant information about the process and its various subcomponents, and note down the different steps.

Then, the list must be put in the correct (chronological) order, and the right standard symbols must be added to the activities. Subsequently, you basically draw a flowchart by connecting the components with lines and arrows.

3. Analyse

After selection and mapping, the process must be analysed. This can be done through a number of questions. Examples of several question you can ask:

- Are there steps in the business process that aren’t necessary?

- Are there steps in the process that take longer than necessary?

- Are there steps in the process that can be carried out in a different order to save time?

- Is there an obvious cause of delays or missed deadlines?

- Which steps are the most important for product quality?

- Which steps carry a significant financial interest?

- How can we make the step more efficient?

The core of the analysis is why. That’s why you should use the Five Whys method.

4. Optimise

When the inefficiencies or problems in the old process have been identified in the previous phase, it’s time to decide how the process can be changed. That depends on several situational factors.

During this phase of Business Process Improvement, the team or the manager will address the underlying causes of the problem. Once the cause has been established, they come up with solutions. During this improvement phase there is brainstorming, introduction of pilots, implementation of solutions, and data collection to measure the improvement. Some tips for optimising include:

- Use the right figures and statistics to measure current and future performance

- Work with employees who have direct experience with the process

- ‘Begin with the end in mind’ – Stephan Covey

- Define the changes that have to be implemented in a very precise way

- Use risk analysis to determine if and where problems might arise

A durable and structured improvement can lead to innovation and an elegant solution that eventually improves the customer experience.

5. Implement

The implementation of a change/innovation is a critical step for the future success of an improvement initiative. If things fail, a company could end up losing more than what the old process cost. There are several factors that contribute to successful implementation.

Therefore, first implement changes on a small scale. This limits risks and allows the new process to be tested. Then compare the performance to the old process to draw a conclusion about the effectiveness of the improvement. If the improvement is approved, it can be rolled out. In the entire organisation, if necessary.

At all times make sure that the information that is used for decision making is accurate. If possible, get it from employees who are directly involved in the process. Don’t forget to keep all stakeholders up to date if it concerns a structurally important or fundamental business process.

6. Monitor

Now that the process issue has been resolved, or the inefficiencies have been ironed out, the team will have to keep the process optimised. In this monitoring phase, the team is focused on developing a monitoring plan, which tracks the statistics about the performance of the process. The statistics, previously determined in phase 4, serve as a foundation for the decision whether or not to change the process in the future.

Sometimes, things don’t go as planned, and a process needs to be restructured or changed on short notice. Even if that’s not the case, Business Process Improvement is still a continuous process. There are almost always changes that can be implemented to improve performance or reduce costs. You can reuse this step-by-step plan again, as well as the tools discussed in this article.

Business Process Improvement (BPI) summary

Business Process Improvement (BPI) is about analysing, optimising, and monitoring business processes. Organisations engage in BPI for a variety of reasons. The reason is often to save costs or time, combat waste, or address issues revealed by performance figures.

Improving business processes is a topic that has been the focus of a great deal of research. As a result, there are several tools available that can support management with implementing changes. One of the best known is the DMAIC from Six Sigma.

In addition, Business Process Improvement (BPI) also uses Business Process Mapping (BPM), as well as cause-effect analysis, value stream mapping, and SIPOC.

The basic process of Business Process Improvement (BPI) consists of six steps, starting with selecting and mapping a business process. When the process has clearly been put on paper, the team starts the analysis. The analysis phase consists of, among others, applying the Five Whys method and considering possible causes of the issue.

In step 4, a solution is proposed for the problem that was established in step 3. The solution is implemented step by step and monitored for some time. Business Process Improvement (BPI) is a continuous process and must be applied to any process in the organisation.

Now It’s Your Turn

What do you think? Do you recognise the explanation of Business Process Improvement (BPI)? Do you know the tools offered in this article? For which business process in your work environment could you use BPI? Do you have any tips or additional comments?

Share your experience and knowledge in the comments box below.

More information

- Adesola, S., & Baines, T. (2005). Developing and evaluating a methodology for business process improvement. Business Process Management Journal, 11(1), 37-46.

- Andersen, B. (2007). Business process improvement toolbox. ASQ Quality Press.

- Bhatt, G. D. (2000). An empirical examination of the effects of information systems integration on business process improvement. International Journal of Operations & Production Management, 20(11), 1331-1359.

- Siha, S. M., & Saad, G. H. (2008). Business process improvement: empirical assessment and extensions. Business Process Management Journal, 14(6), 778-802.

- Zellner, G. (2011). A structured evaluation of business process improvement approaches. Business Process Management Journal, 17(2), 203-237.

How to cite this article:

Janse, B. (2019). Business Process Improvement (BPI). Retrieved [insert date] from Toolshero: https://www.toolshero.com/quality-management/business-process-improvement-bpi/

Original publication date: 06/20/2019 | Last update: 09/04/2023

Add a link to this page on your website:

<a href=”https://www.toolshero.com/quality-management/business-process-improvement-bpi/”>Toolshero: Business Process Improvement (BPI)</a>